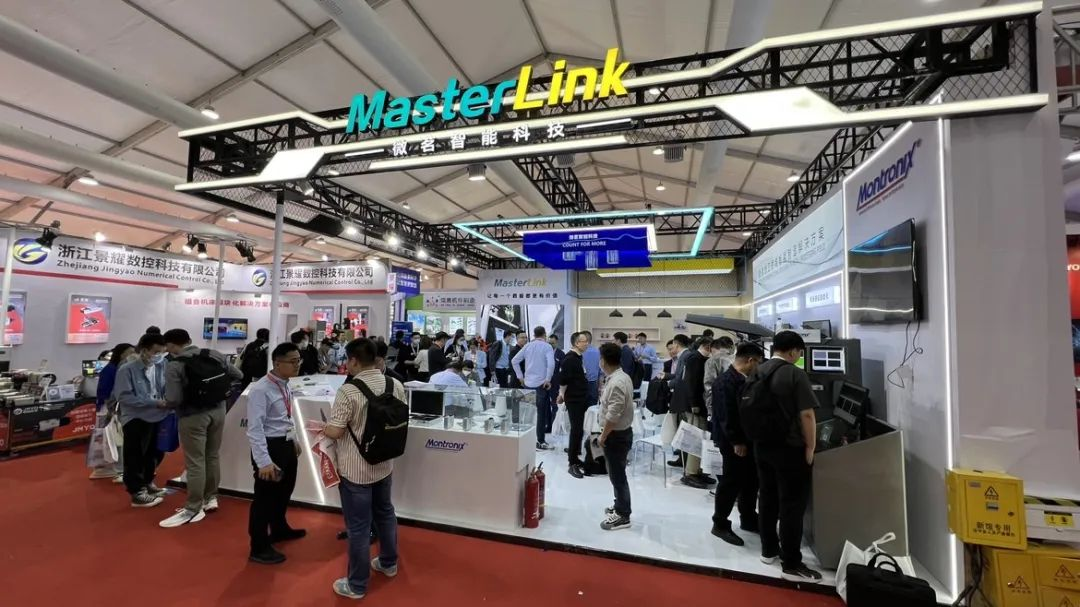

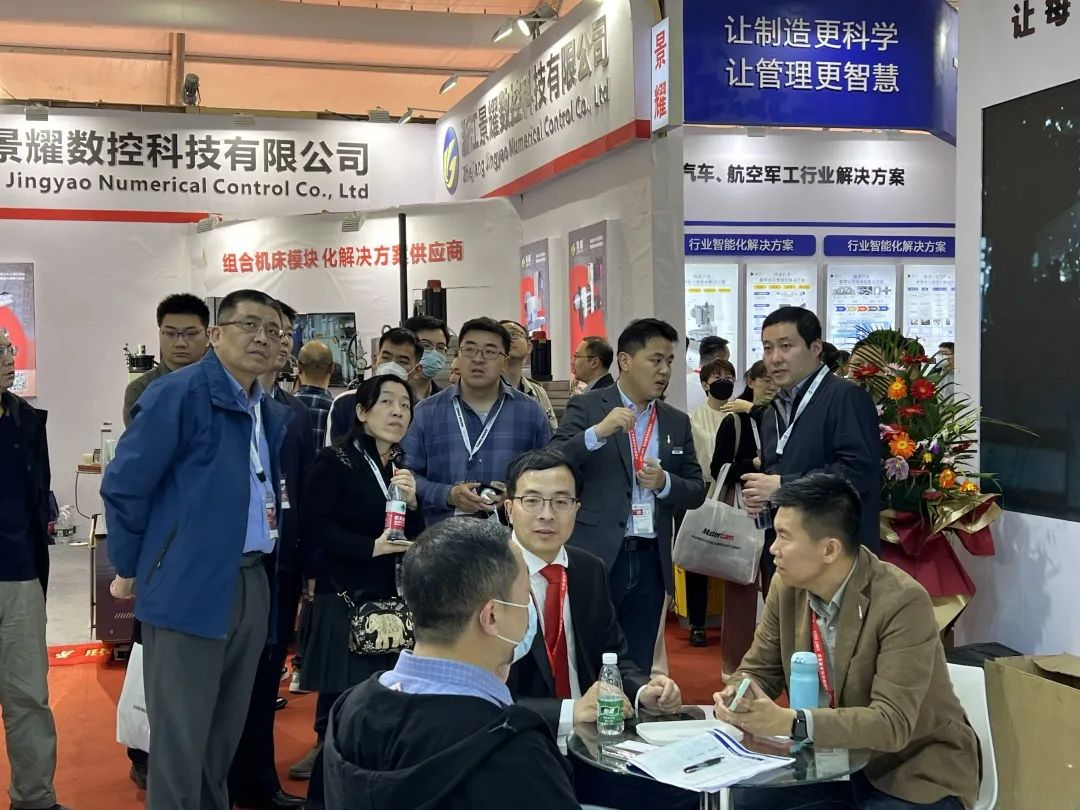

On April 15th, the 18th China International Machine Tool Exhibition closed in Beijing. The appearance of products such as Weiming Intelligent Machine Tool Perception Intelligence, Production Line Flexibility Intelligence, and Workshop Collaboration Intelligence at this exhibition has attracted numerous domestic and foreign visitors to visit and exchange ideas.

Exciting Review

在本次展会上,微茗智能不仅接待了来自全球的观展客户,为客户提供了专业的金属加工智能制造解决方案,更有客户现场签单。

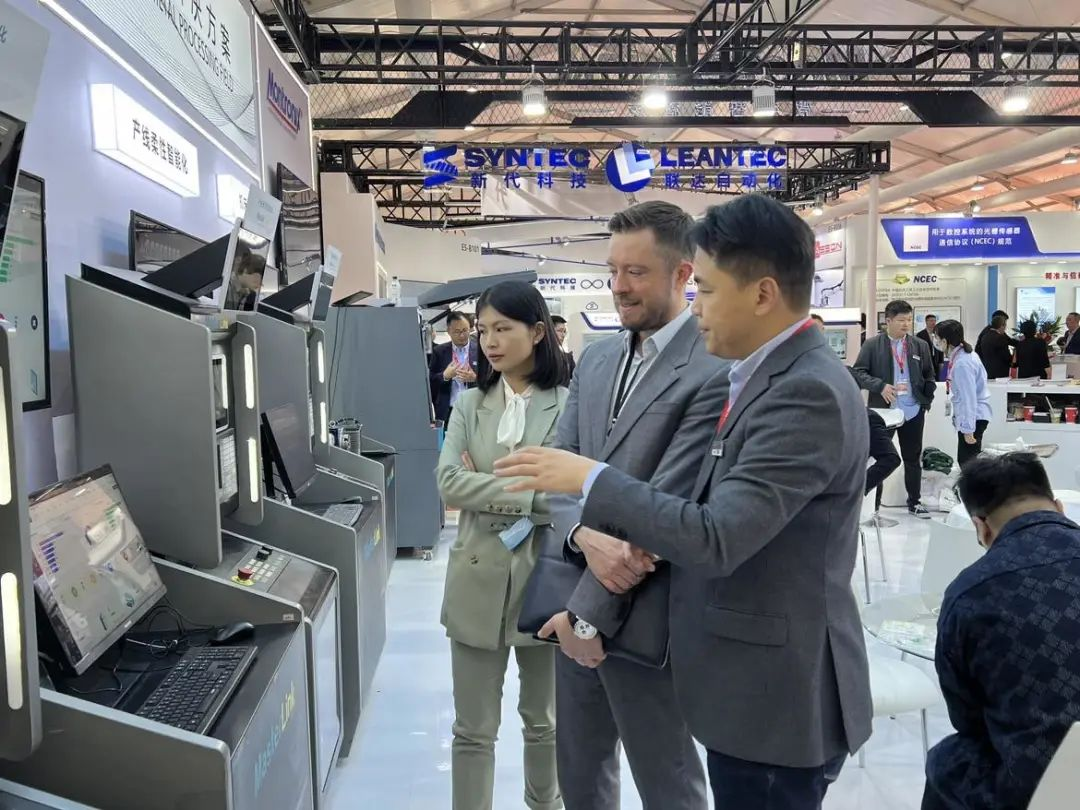

Exhibited products

Intelligent machine tool perception

Collision protection system:

Equipment collision is difficult to avoid in actual production. This protection system can output IO to the machine tool system within 1ms of detecting the collision signal, and make a timely shutdown response to minimize collision losses.

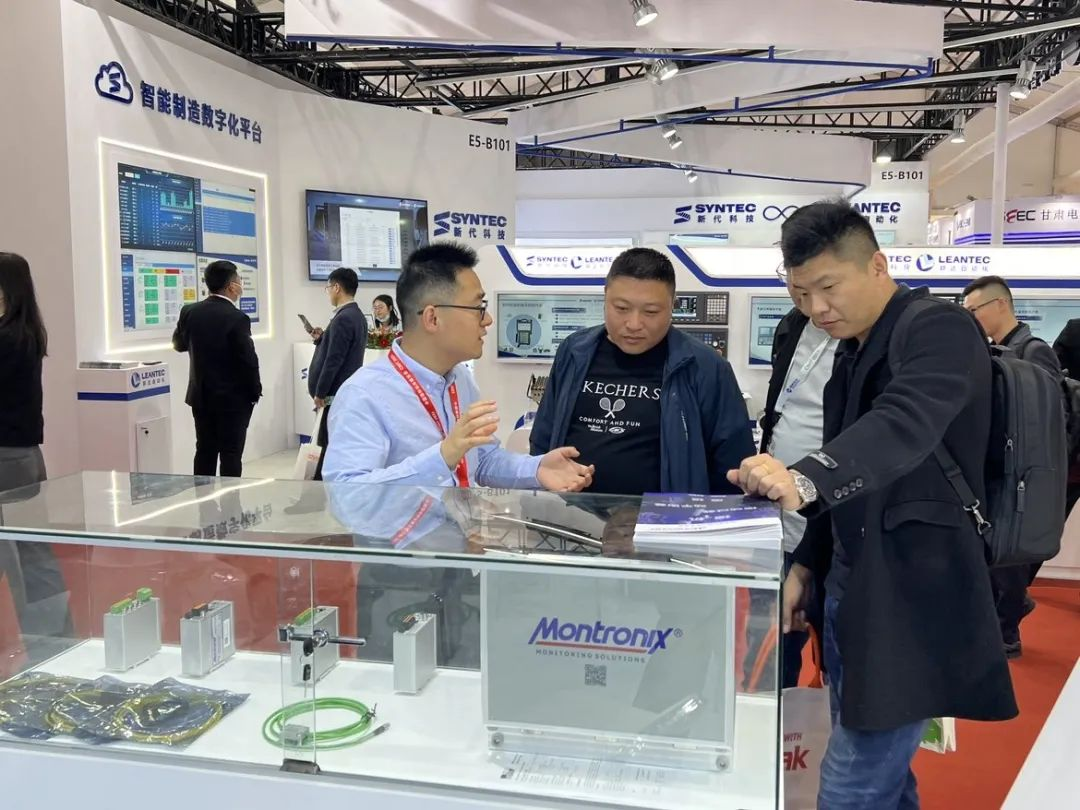

Tool monitoring system:

The Montronix tool monitoring system mainly monitors tool breakage, chipping, wear, loss during the machining process, as well as abnormalities in the machining environment such as tooling and component quality that affect the machining quality. This system is equipped with various sensor forms, specifically designed for different processing processes to achieve accurate monitoring of processing data. Help reduce production costs and improve machine tool efficiency.

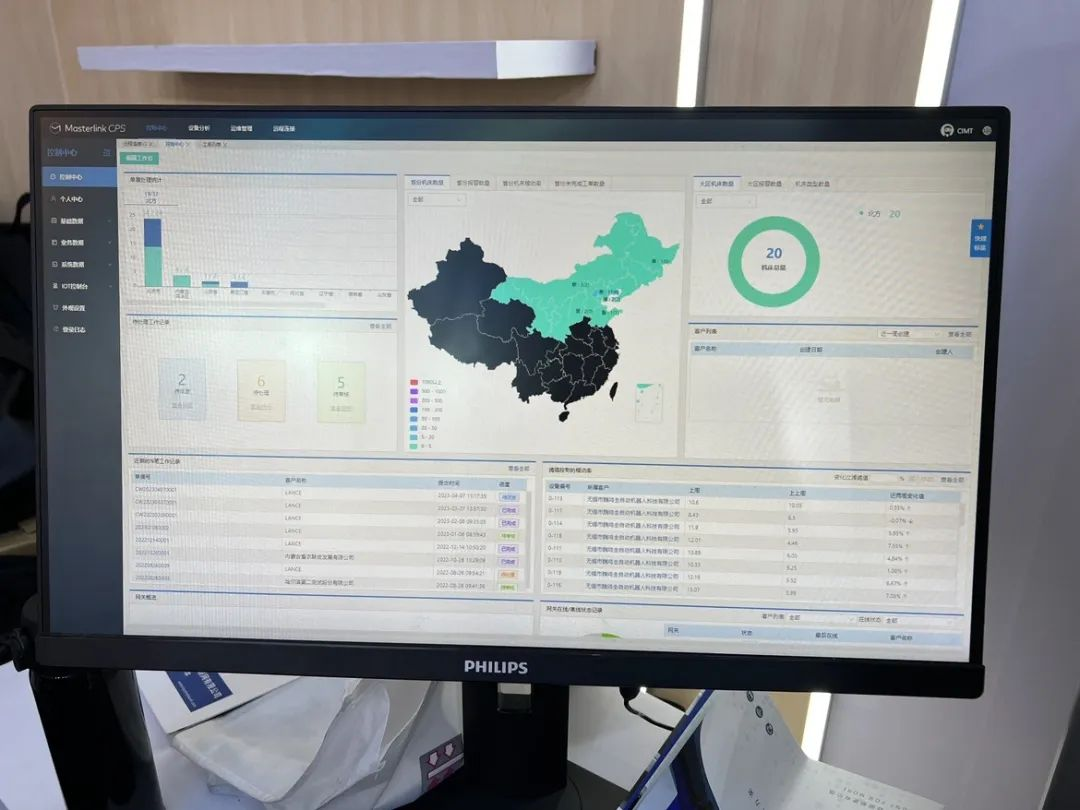

Portable diagnostic equipment: Portable diagnostic equipment can run through the entire process of machine tool equipment use, including the entire lifecycle of equipment manufacturers from assembly, testing, factory delivery, after-sales service, trading, production enterprises' new machine entry, point inspection, maintenance, process optimization, and life management. External 4/5-axis turntable servo driver: independently developed the MCS machine tool additional axis servo drive control system, without opening CNC system permissions, perfectly compatible with FANUC, Mitsubishi, Siemens, Seiko and other CNC systems, achieving the positioning processing requirements of the machine tool turntable at low cost and high cost performance. Industrial Equipment Operation and Maintenance Cloud: By combining electrical data with sensor intelligent data, remote CNC system screen synchronization is achieved, and enterprise equipment maintenance costs are reduced through customer management, after-sales management, equipment management, remote diagnosis, etc.

Flexible and intelligent production line

Line Management System (LMS) is an intelligent management system for production lines, which realizes the collection and analysis of production line information data, production work order process management, and full process production data traceability in automated production lines and mass production processes; The LMS system provides data support for machining automation lines, helping traditional automation lines upgrade to intelligent, information-based, and lean digital production lines. Flexible Manufacturing System (FMS) is a set of process equipment based on CNC machine tools and other automation, which is an organic combination of line control system and material automatic storage and transportation system. The flexible manufacturing system is composed of three subsystems: processing, logistics, and information flow. It achieves the automation of material flow and information flow on the basis of processing automation by connecting equipment data within the line and managing work orders.

Intelligent workshop collaboration

The collaborative manufacturing management system of Weming Self developed Workshop is a comprehensive information management system for the workshop business executive level of manufacturing enterprises. Based on the relevant data of human, machine, material, method, environment and measurement, it realizes the collaborative interaction, management, intelligent factory management and Lean manufacturing of the business level.

Group photo of all staff