SME collaborative manufacture management cloud

Through MasterLink I0T data acquisition products (S2 or MT Pad)+lightweight MES production and manufacturing management system, workshop digitalization and intelligent production can be realized

SME collaborative manufacture management cloud

Through MasterLink I0T data acquisition products (S2 or MT Pad)+lightweight MES production and manufacturing management system, workshop digitalization and intelligent production can be realized

Home / SME collaborative manufacture management cloud

Pain points in workshop production

01

The use of process documents is confused, and it is difficult to control

02

The production plan is complicated, and the delivery date of orders cannot be controlled

03

Warehouse material management disorder, processing process is not transparent

04

Equipment efficiency monitoring is difficult and repetitive labor cost is high

What is the shop floor Co-manufacturing Management Cloud

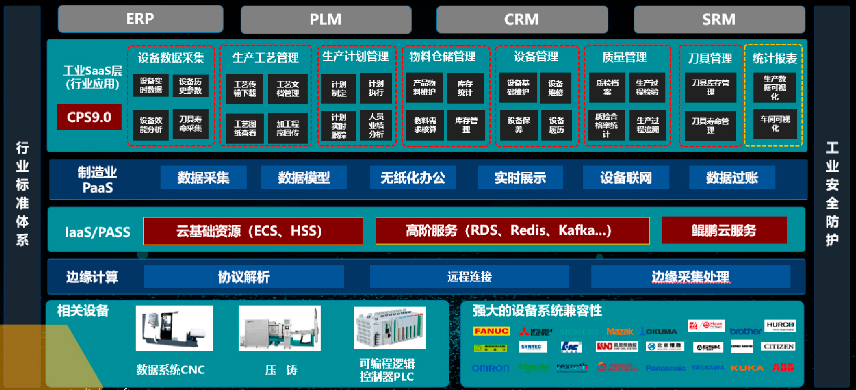

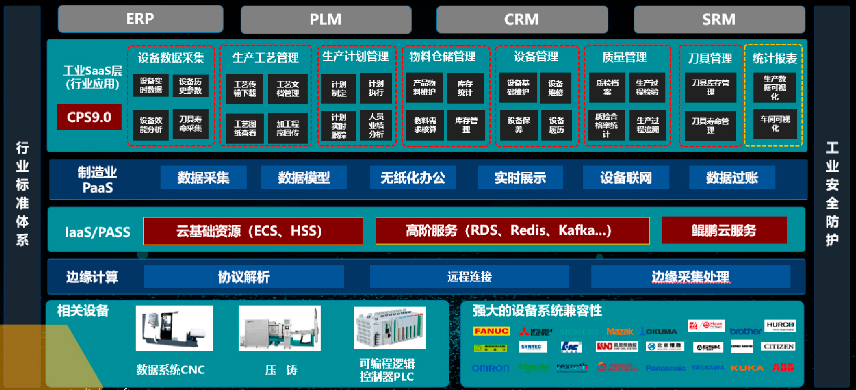

Workshop collaborative manufacturing management cloud, based on cloud server, using cloud technology software architecture, through micro Ming IOT data acquisition products (S2 or MTPad) lightweight MES production and manufacturing management system, so as to realize workshop digitalization and intelligent production.

With edge computing and SaaS application layer as the core, the product focuses on the machine tool industry, focusing on the production and application scenarios of metal processing with multiple varieties and small batches, few varieties and large quantities, and single piece flow. Through standardized and lightweight application apps, MTPad, S2 hardware and other products, the production management informatization transformation and upgrading of micro, small and medium-sized enterprises are realized.

Traditional Customized MES and Microservice Architecture MES (Saas Applications)

Micro service architecture of MES based on the equipment side, real-time acquisition data applications of lay particular stress on, pay attention to the fast data interaction, coordination and efficient production, through the device object, person, machine, material, method, ring, measuring data collaborative applications, each information data distribution to need to post, let everybody to give full play to their professional and skills, according to effective collaboration, Thus, the overall efficiency of the factory can be improved.

Traditional customized MES

Custom from scratch, high cost and high investment

Highly integrated, functions can not be split

Deep customization, new business needs heavy money

Local deployment, focusing on process control

Microservice Architecture MES.(Saas Applications)

Save investment, low cost and high return

On-demand configuration, fast and flexible online

Keep iterating and subscribe for updates forever

Cloud deployment, focusing on efficient collaboration

Three versions for sale

The primary version

Realize the function

● Collect and analyze device data, and export the analysis content in EXCEL format

● Through the visual kanban, the workshop staff can know the operation of the station in real time, the execution of the production plan, and quickly respond to the equipment fault alarm

● Mobile phone terminal to realize real-time data query and trace the historical data query

The standard version

Realize the function

● Collect and analyze equipment data, analyze equipment status data (including alarm), process data and parameter data

● CNC equipment processing program version management, support upload between machine tools

Download to view the process drawing file on MTPad

● Through visual kanban, the workshop staff can know the station movement in real time

Transfer situation, production plan execution, quick response to equipment failure alarm

● Mobile phone terminal to realize real-time data query and trace the historical data query

The lamp module, the abnormal lack of material, abnormal problems to achieve fast call

Rrofessional edition

Realize the function

● Collect and analyze equipment data, analyze equipment status data (including alarm), process data and parameter data

● CNC equipment processing program version management, support and machine upload and download, can view the process drawing file on MTPad

● Through the visual kanban, the workshop staff can know the operation of each station in real time, the execution of the production plan, and quickly respond to the equipment fault alarm

● According to the equipment production situation, reasonable production plan, work order distribution, production process data paperless

● Maintain the equipment, the platform can record the corresponding maintenance details

● To carry out inventory management for the material in and out of storage, moving storage, storage records can be presented through the report form

● The product inspection data entry, inspection records can be presented through the report, the production process quality data can be traced

● Provide installation light module for abnormal calls of employees

The lamp module, the abnormal lack of material, abnormal problems to achieve fast call

Product advantages

Innovative hardware products in the industry to achieve human-computer interaction, cost-effective!

Perfect data acquisition capability, compatible with more than 95% of the CNC systems on the market!

East China was the first to engage in machining Saas product research and development team!

The product update is fast and convenient, and the scheme is more suitable for business scenarios!

Rapid deployment

Light implementation

Integratable

Easy operations

Strong safety

Hardware advantage

Software advantage

Pain points in workshop production

01

The use of process documents is confused, and it is difficult to control

02

The production plan is too complicated to control the order delivery date

03

The materials in the warehouse are poorly managed and the processing process is not transparent

04

It is difficult to monitor equipment efficiency and the cost of repetitive labor is high

What is workshop collaborative manufacturing management cloud

The workshop collaborative manufacturing management cloud is based on the cloud server and uses the cloud technology software architecture to lightweight the MES production and manufacturing management system through Weming IOT data acquisition products (S2 or MTPad), so as to realize the workshop digital and intelligent production.

With edge computing and SaaS application layer as the core, the product focuses on the machine tool industry, focusing on the production application scenario of metal processing with multiple varieties and small batches, small varieties and large batches, and single piece flow. Through standardized and lightweight application APP, MTPad, S2 hardware and other products, the production management information transformation and upgrading of small and medium-sized enterprises can be realized.

Traditional customized MES and micro service architecture MES (Saas application)

The micro service architecture MES is based on the device side, focusing on real-time data acquisition applications, focusing on rapid data interaction, collaborative and efficient production. Through the equipment Internet of Things, it realizes the collaborative application of multiple data such as people, machines, materials, methods, environment, and measurement, and distributes various information and data to the required posts, so that everyone can give full play to their own expertise and skills, perform their own duties, and collaborate effectively, so as to improve the overall efficiency of the factory.

Traditional customized MES

Customized from scratch, high cost and high investment

Highly integrated, functions cannot be separated

Deep customization, new business needs heavy money

Local deployment, focusing on process control

Microservice architecture MES. (Saas application)

Saving investment, low cost and high return

On demand configuration, fast and flexible online

Continuous iteration, subscription and permanent upgrade

Cloud deployment, focusing on efficient collaboration

Three versions for sale

Starter Edition

Implementation function

● Data collection and analysis of equipment, and analysis content supports EXCEL format export

● Through the visual kanban, workshop personnel can understand the operation of the station and the implementation of the production plan in real time, and quickly respond to the equipment failure alarm

● The mobile phone terminal realizes real-time data query and retrospective query of historical data

Standard edition

Implementation function

● Equipment data collection and analysis, data analysis for equipment status (including alarm), process and parameter data

● CNC equipment processing program version management, supporting uploading between machine tools

Download and view process drawing files on MTPad

● Through visual signage, workshop personnel can understand station operation in real time

Change status, production plan implementation status, and quickly respond to equipment failure alarm

● The mobile phone terminal realizes real-time data query and retrospective query of historical data

● The lamp module can quickly call for abnormal material shortage and abnormal problems

professional edition

Implementation function

● Data collection and analysis of equipment, data analysis for equipment status (including alarm, etc.), process and parameter data

● CNC equipment processing program version management, which supports uploading and downloading with the machine tool, and can view process drawing files on MTPad

● Through visual kanban, workshop personnel can understand the operation of each station and the implementation of production plan in real time, and quickly respond to equipment failure alarm

● According to the equipment production, reasonably formulate the production plan, dispatch the work order, and make the production process data paperless

● Maintain the equipment, and the platform can record the corresponding maintenance details

● Inventory management shall be carried out for the warehousing and transfer of materials, and the warehousing and issue records can be presented in the form of reports

● Input the inspection data of products, the inspection records can be presented through reports, and the quality data of the production process can be traced

● Provide lighting module for abnormal calls of current employees

● The lamp module can quickly call for abnormal material shortage and abnormal problems

Product advantages

Innovative hardware products in the industry to achieve human-computer interaction, cost-effective!

Perfect data acquisition capability, compatible with more than 95% of the CNC systems on the market!

East China was the first to engage in machining Saas product research and development team!

The product update is fast and convenient, and the scheme is more suitable for business scenarios!

Rapid deployment

Light implementation

Integratable

Easy operation and maintenance

Strong security

Hardware advantages

Software advantages

COUNT FOR MORE

Please leave your contact information and our customer manager will contact you as soon as possible

COUNT FOR MORE

Please leave your contact information and our customer manager will contact you as soon as possible

Contact us

Hotline

400-828-3830

E-mail

Sales@wimisoft.com

-

Official account

Official account

Copyright © 2021 MasterLink All Rights Reserved.

苏ICP备19005118号-1

Product trial