Collision Detection

Spindle collision protection tools necessary for precision machine tools

Collision Detection

Spindle collision protection tools necessary for precision machine tools

We can help you realize these functions!

After installing PulseNG system, your machine will be provided with 7*24h real-time protection.

Without limited to the type of the NC system, our system is compatible with Siemens, Bosch Rexroth, Heidenhain, Fanuc, Mitsubishi.

We can recognize:

●Collision in any direction in the case of fast or slow feeding

●Vibration overload, stress overload and power overload

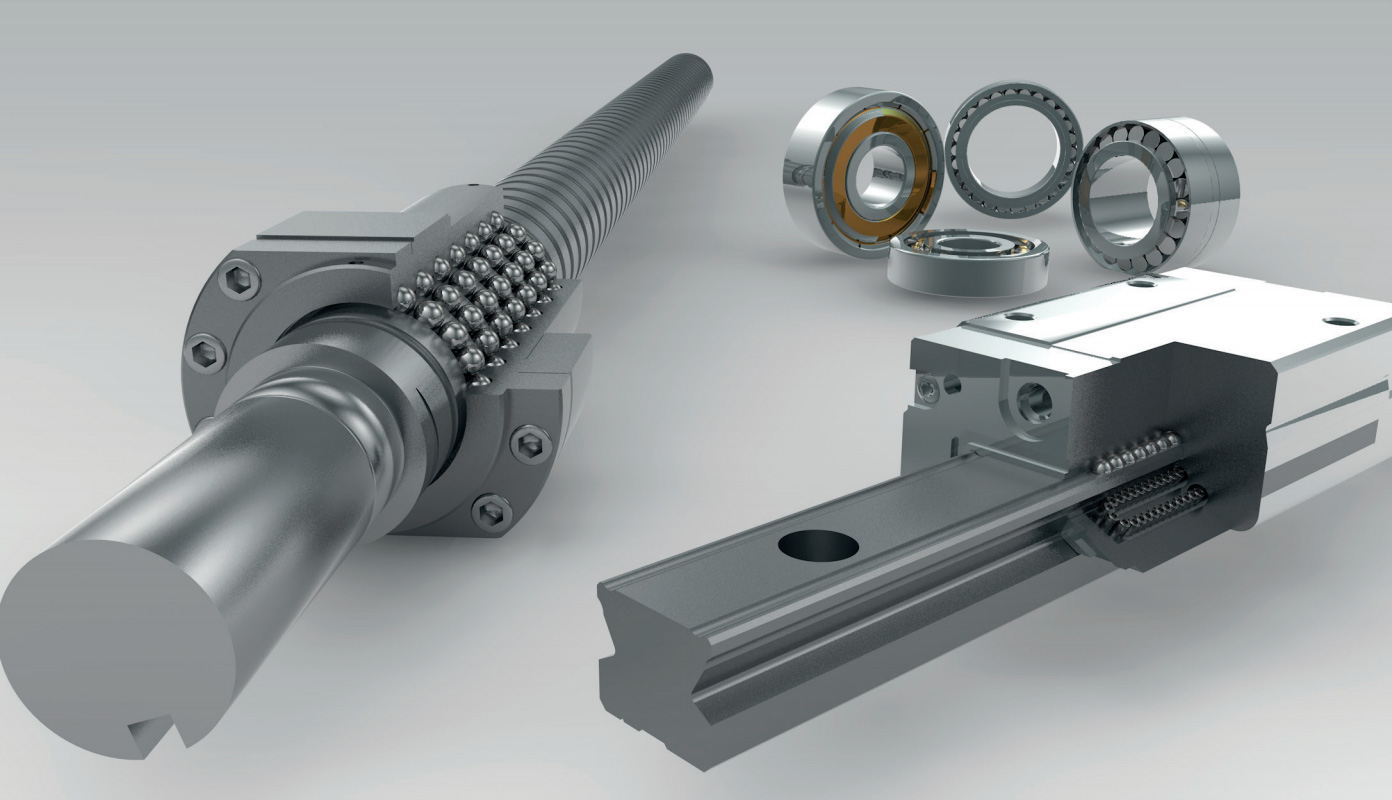

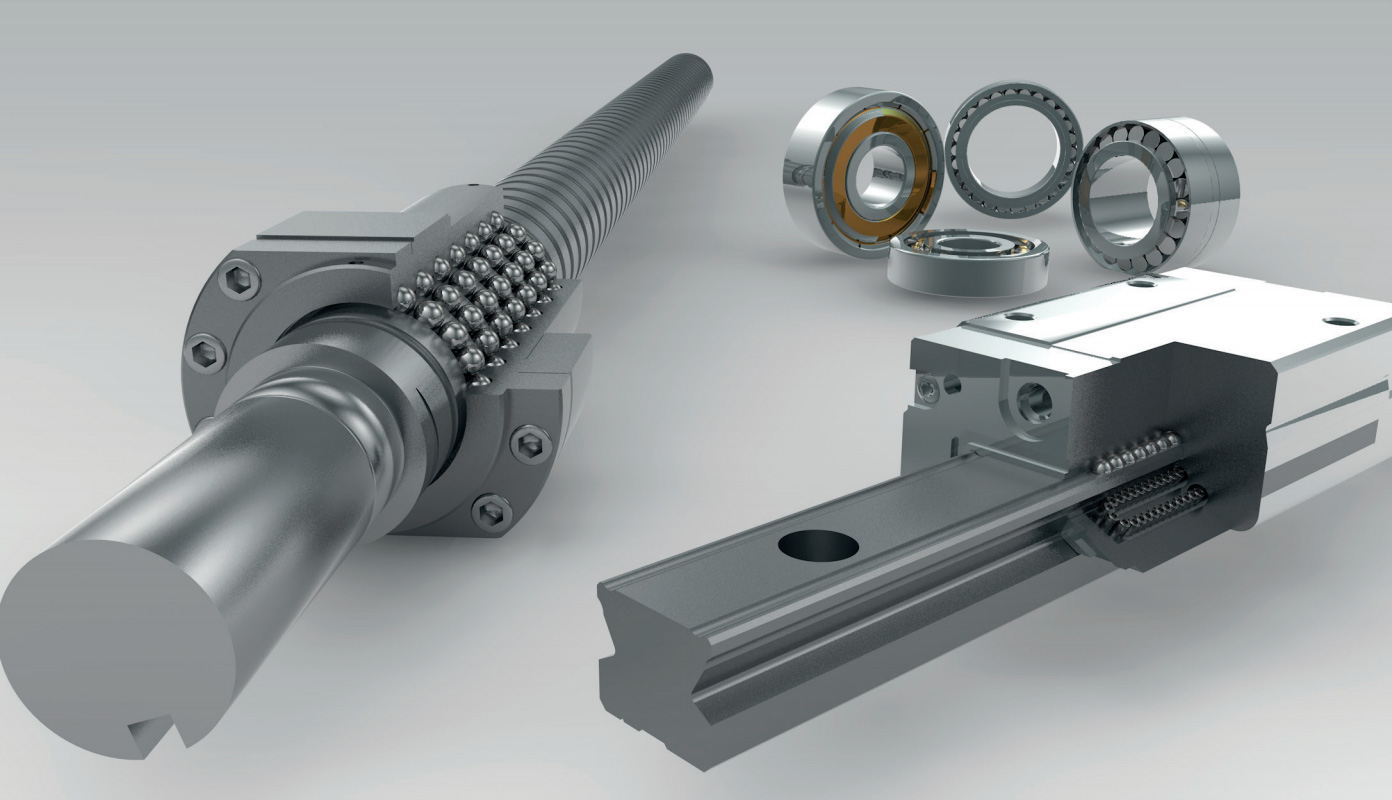

●Service condition of machine parts (ball screw, reel, spindle, etc.)

Response time <1ms*

●Emergency shutdown

●NC shutdown

*This time is only effective under the basic configurations. As the system configurations are different, the response time will be different too.

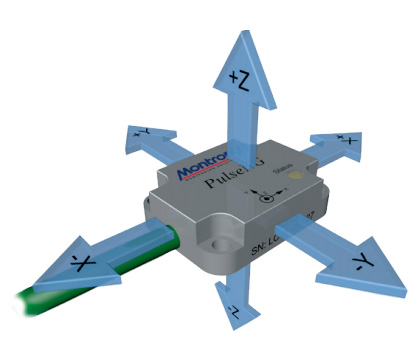

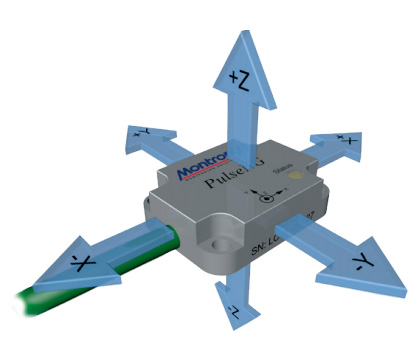

Measuring coordinate axis of PulseNG sensor

■ Multiple combination configurations

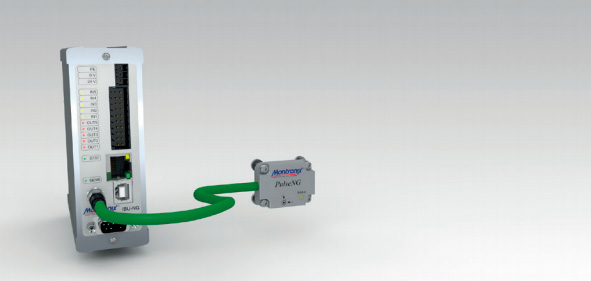

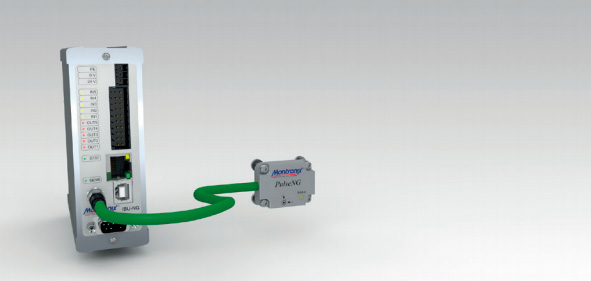

Basic configuration

(As shown in the figure: IBU-NG signal processing unit+PulseNG sensor)

Only one sensor is needed for effective protection

Expansion configuration

(As shown in the figure: MUX-NG multiplexer+StrainLink sensor+SL. A-NG signal amplifier+PulseNG M12 sensor is added, which is one of the possibilities to expand) Multiple sensors can be connected, which can combine the measurement of multiple different physical variables to achieve more comprehensive protection

Three plans for one set of products

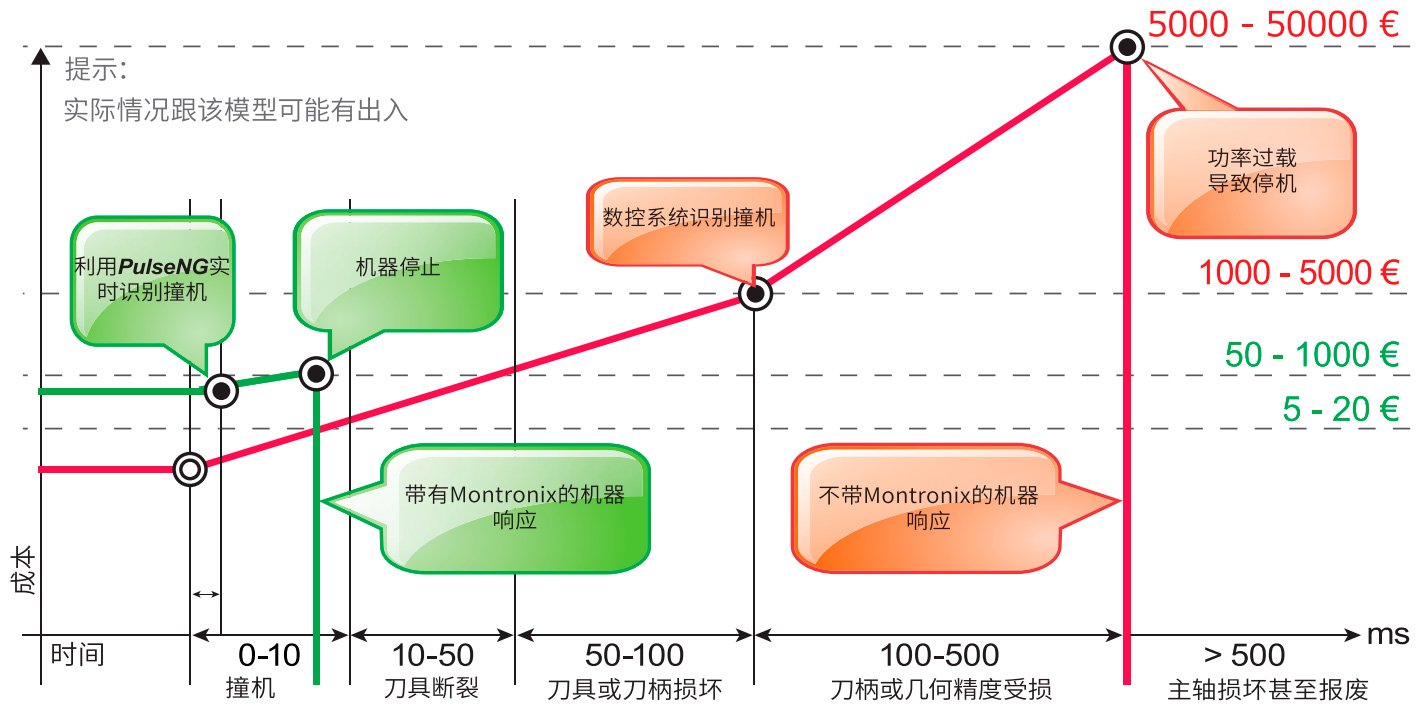

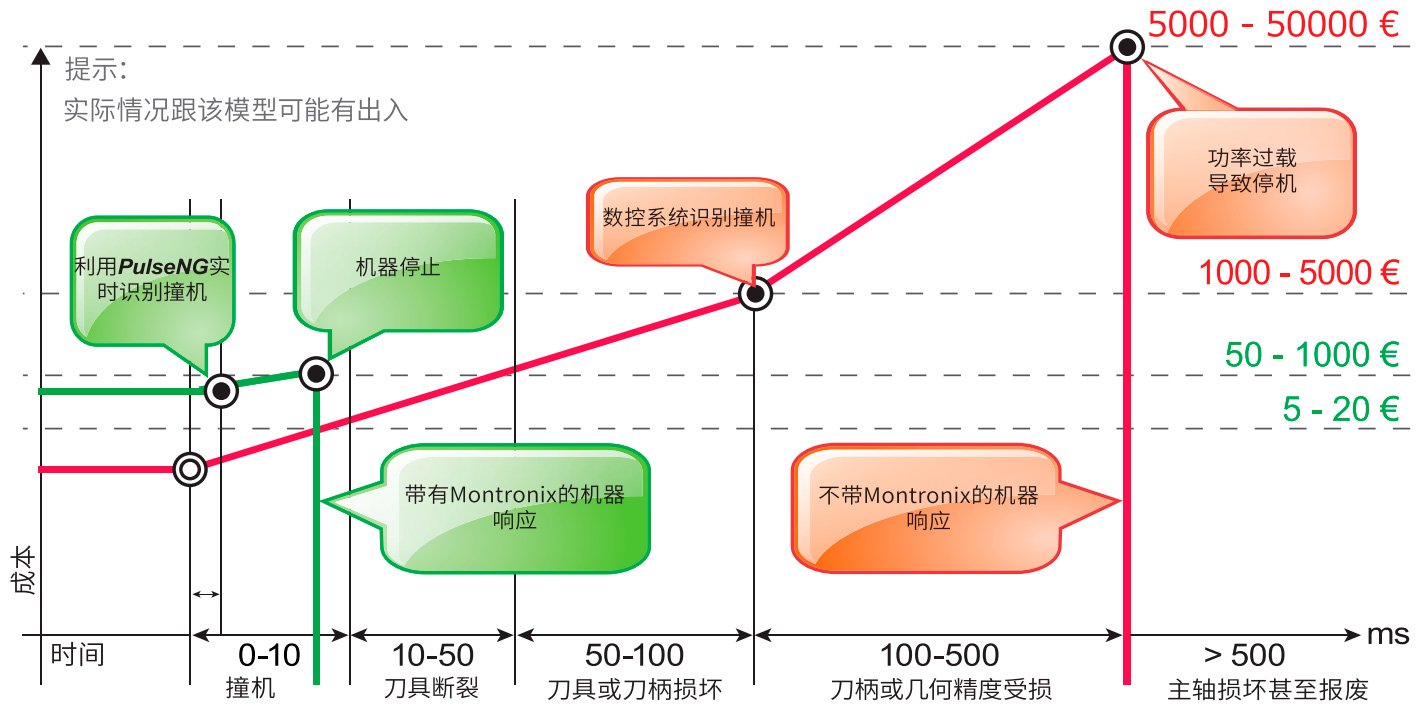

■ Comparison of machine protection methods

Fast response - improve machine tool utilization and significantly reduce cost

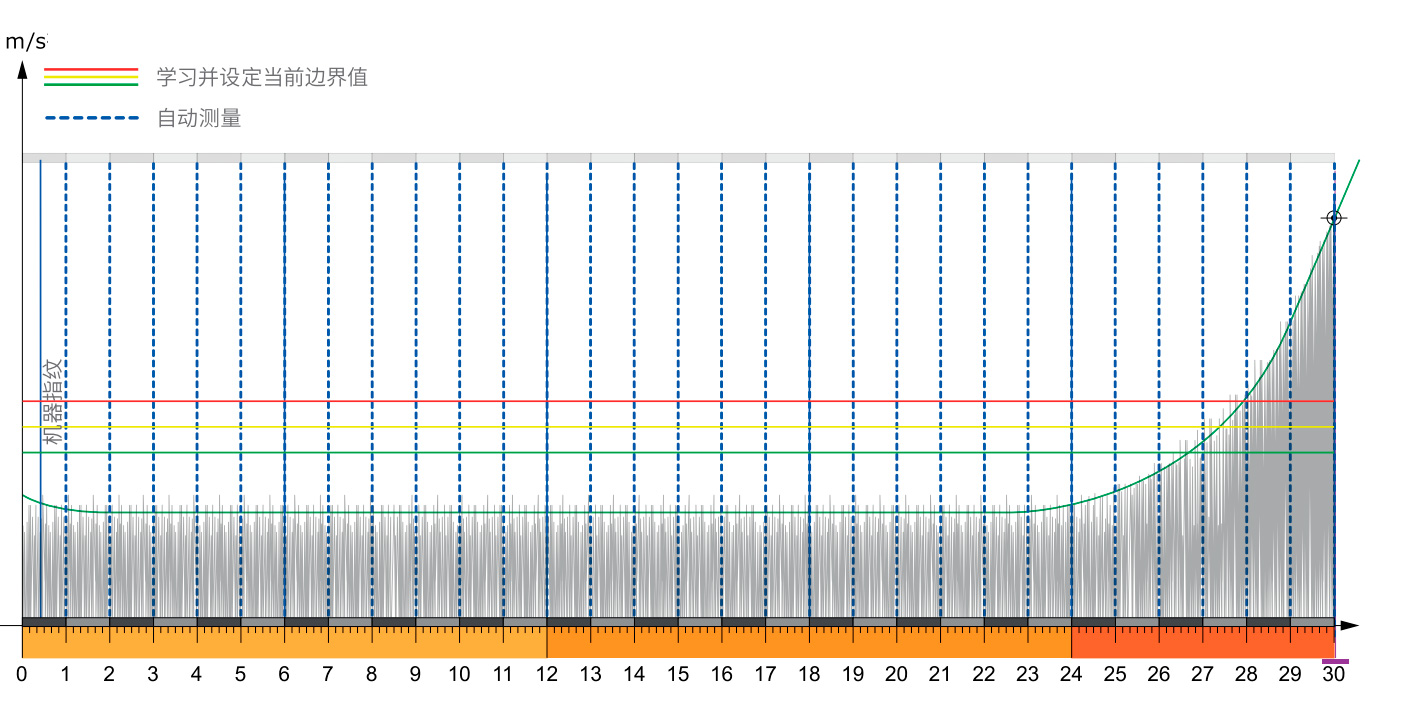

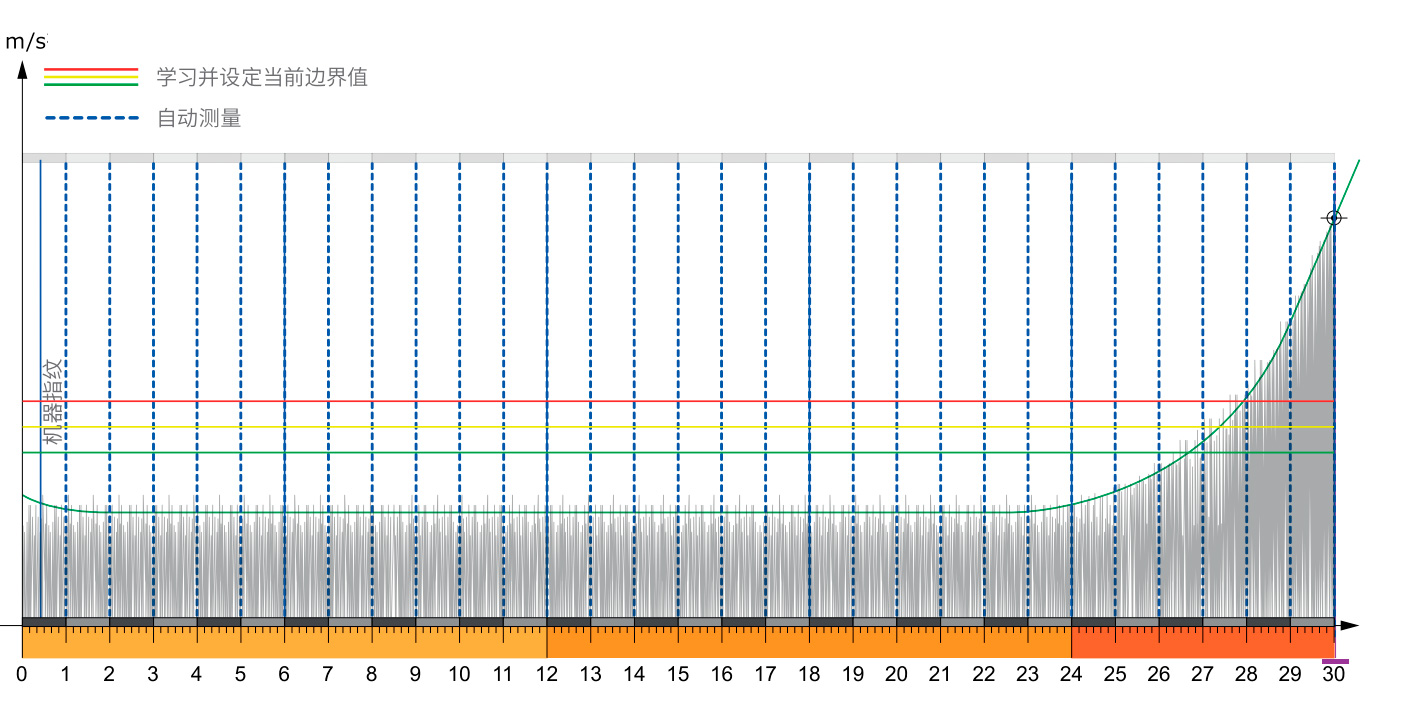

■ Fully automatic machine condition diagnosis - wear trend curve

Automatic alarm prompt in case of wear or damage

Regular automatic measurement, early identification of wear on machine parts

Application examples

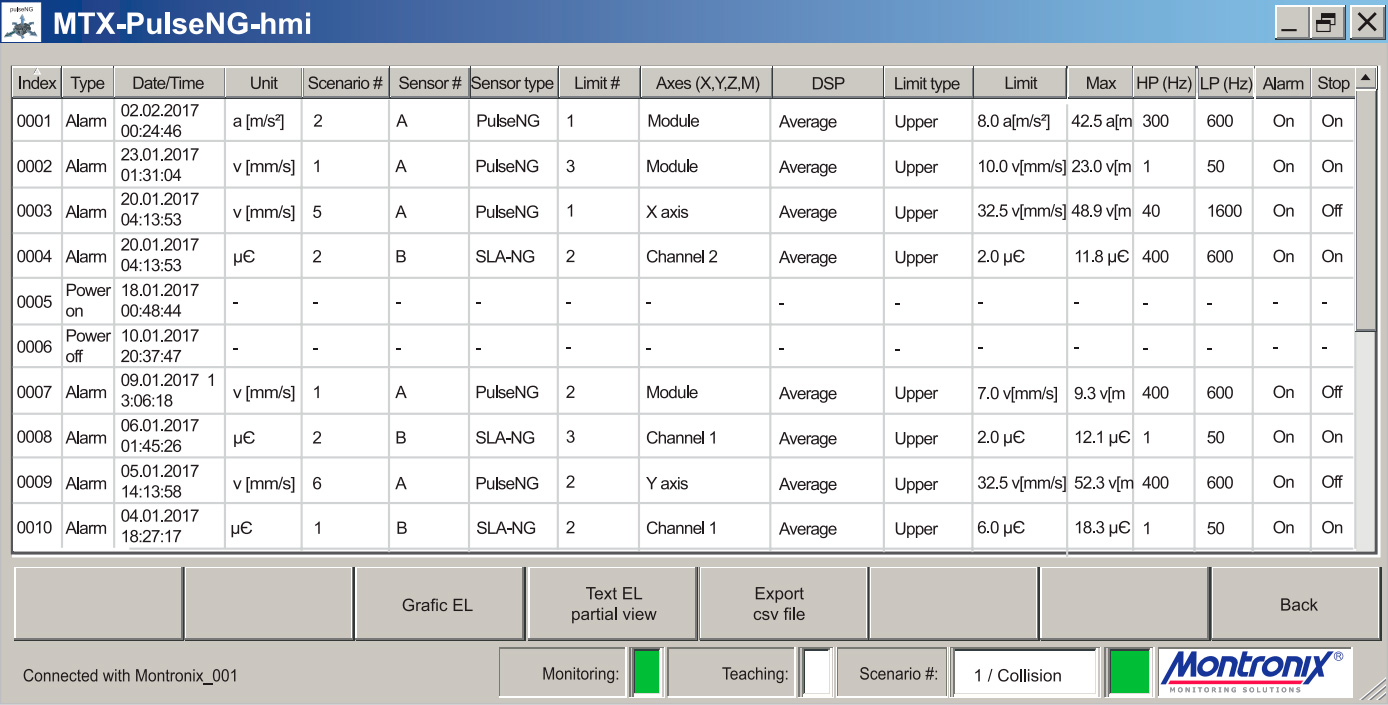

■ Text event recorder

Any abnormal event beyond the set boundary value will be recorded in the system ring recorder and cannot be deleted or changed.

The text event recorder in the signal processing unit can store more than 4000 text event logs, and can be exported in tabular form at any time.

The image event recorder in the signal processing unit can store 64 image event logs

(5 seconds before and after the event) - Please refer to the example on the next page:

Application examples

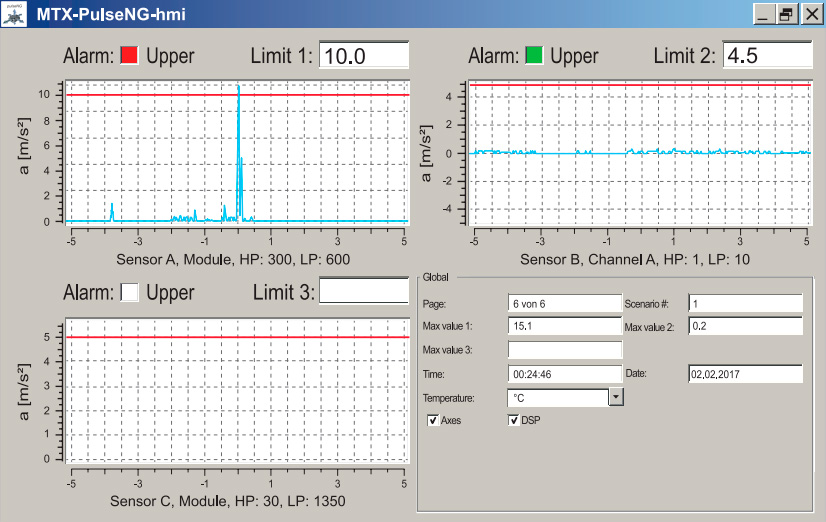

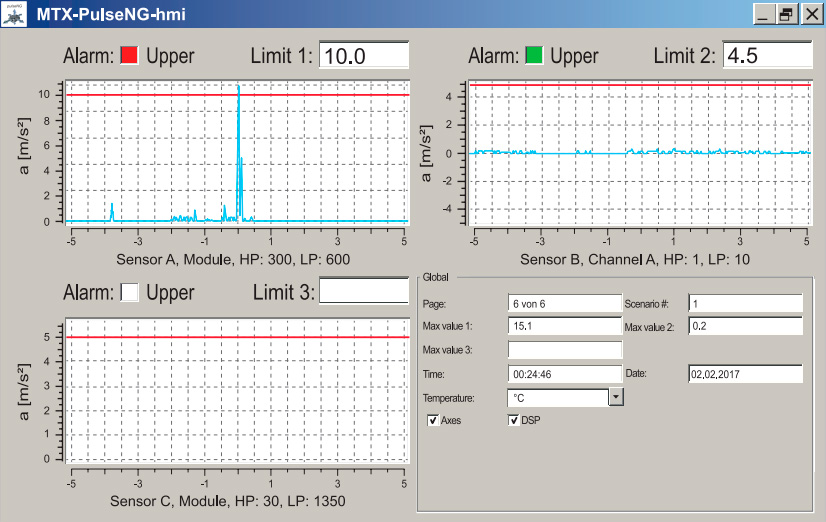

■ Image event recorder

Collision

Boundary 1: fast collision recognition

Boundary 2: Slow Impact Identification

Boundary 3: Not enabled

◆ Response time<1 ms

◆ Emergency stop

◆ Try to reduce the subsequent cost of collision

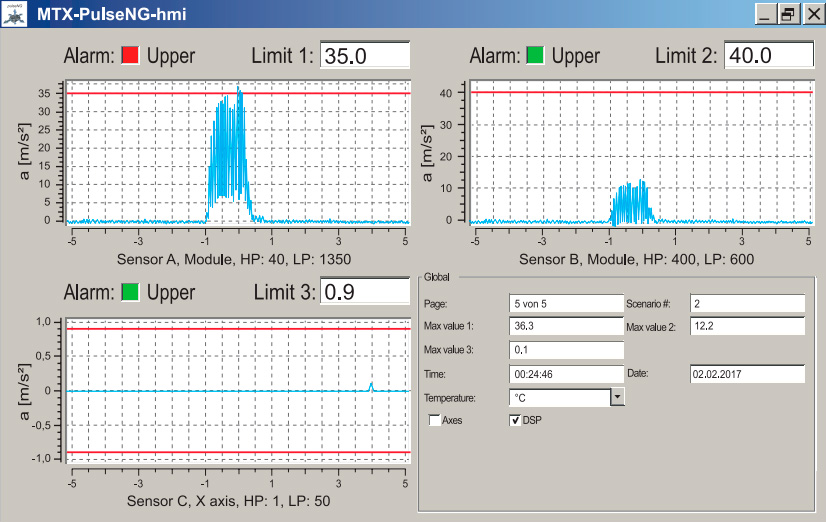

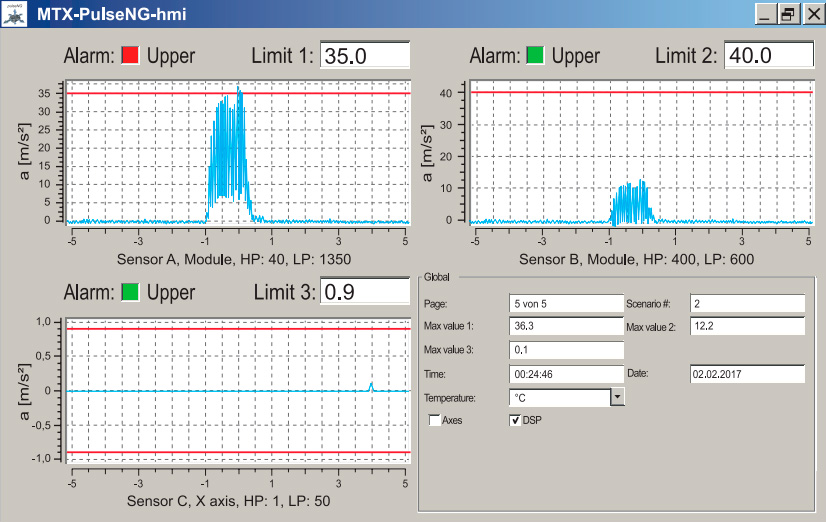

Vibration overload

Boundary 1: Vibration overload

Boundary 2: Vibration overload

Boundary 3: surface deformation

◆ Response time<1 ms

◆ NC shutdown and feed speed adjustment

◆ The boundary value can be customized according to the actual situation of the customer

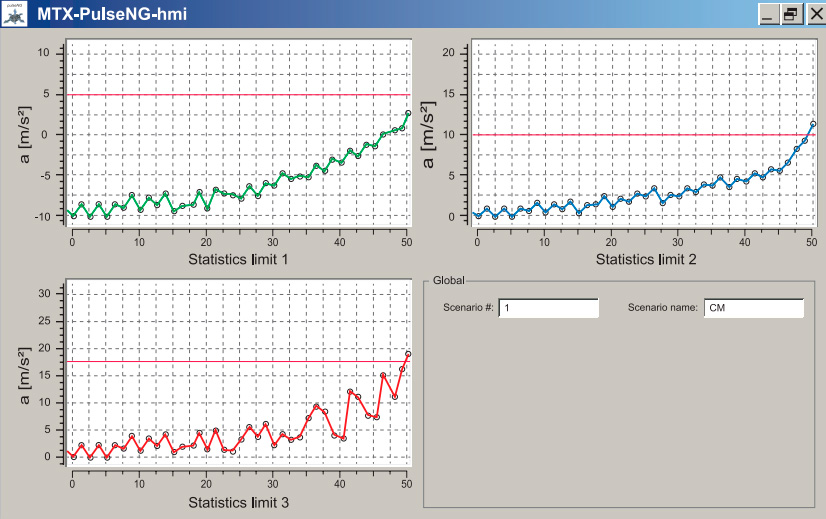

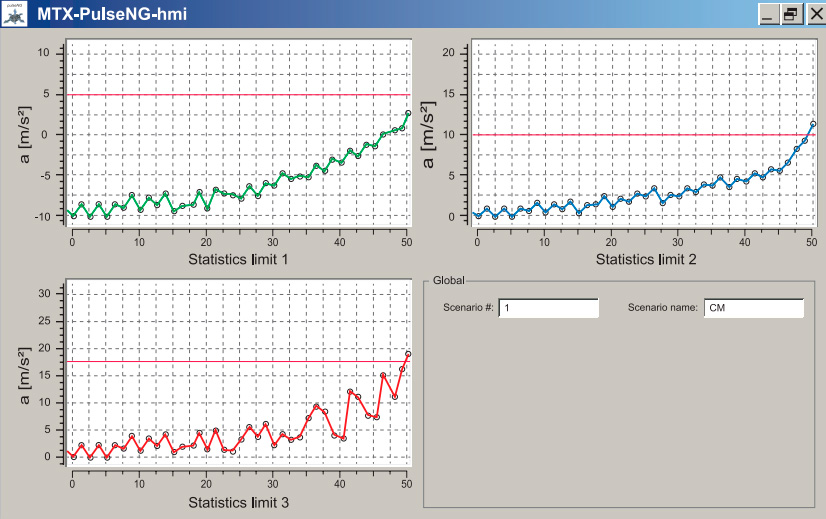

Fully automatic machine status diagnosis

Boundary 1: statistical curve of motion axis

Boundary 2: Statistical curve of transverse axis

Boundary 3: Vertical axis statistical curve

◆ Early identification of wear on machine parts

◆ Preventive maintenance

◆ Automatically measure and alarm for wear

Industry 4.0

■ Applicable to Industry 4.0

◆ All measurement data are transmitted to the LAN in a universal format for big data analysis and management

◆ Promote centralized and unified management of machines

◆ Help to establish an overview of all machine tool use conditions

◆ Facilitate planned and preventive equipment maintenance

◆ Provide client server function

Widely applicable

Machining center

Lathe

Grinding machine

Drilling/milling machine

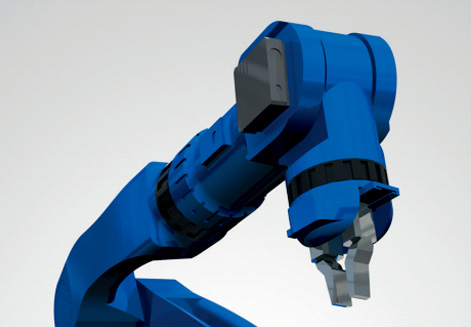

Manipulator

Conveyor

Automatic monitoring of the use of important parts of the machine

Crash protection video

Our business has been distributed all over the world

By contracting from conception to turnkey, we can provide you with a complete set of service procedures: conception, actual installation, operation commissioning, technical training, production optimization and big data required by industrial 4.0!

We can help you realize these functions!

After installing the PulseNG system, your machine will be protected 24 hours a day.

We are not limited by the type of NC system, and are compatible with Siemens, Bosch Rexroth, Heidenhain, Fanuc, Mitsubishi

We can identify:

● Collision in any direction, whether in rapid feed or slow feed

● Vibration overload, force overload and power overload

● Service conditions of machine components (ball screw, spool, spindle, etc.)

Response time<1ms*

● Emergency stop

● NC shutdown

*This time is only valid in the basic configuration. The response time varies with the system configuration.

PulseNG传感器的测量坐标轴

■ Multiple combination configurations

Basic configuration

(As shown in the figure: IBU-NG signal processing unit+PulseNG sensor)

Only one sensor is needed for effective protection

Expansion configuration

(As shown in the figure: MUX-NG multiplexer+StrainLink sensor+SL. A-NG signal amplifier+PulseNG M12 sensor is added, which is one of the possibilities to expand) Multiple sensors can be connected, which can combine the measurement of multiple different physical variables to achieve more comprehensive protection.

Three plans for one set of products

■ Comparison of machine protection methods

Fast response - improve machine tool utilization and significantly reduce cost

■ Fully automatic machine condition diagnosis - wear trend curve

Automatic alarm prompt in case of wear or damage

Regular automatic measurement, early identification of wear on machine parts

Application examples

■ Image event recorder

Collision

Boundary 1: fast collision recognition

Boundary 2: Slow Impact Identification

Boundary 3: Not enabled

◆ Response time<1 ms

◆ Emergency stop

◆ Try to reduce the subsequent cost of collision

Vibration overload

Boundary 1: Vibration overload

Boundary 2: Vibration overload

Boundary 3: surface deformation

◆ Response time<1 ms

◆ NC shutdown and feed speed adjustment

◆ The boundary value can be customized according to the actual situation of the customer

Fully automatic machine status diagnosis

Boundary 1: statistical curve of motion axis

Boundary 2: Statistical curve of transverse axis

Boundary 3: Vertical axis statistical curve

◆ Early identification of wear on machine parts

◆ Preventive maintenance

◆ Automatically measure and alarm for wear

Industry 4.0

■ Applicable to Industry 4.0

◆ All measurement data are transmitted to the LAN in a universal format for big data analysis and management

◆ Promote centralized and unified management of machines

◆ Help to establish an overview of all machine tool use conditions

◆ Facilitate planned and preventive equipment maintenance

◆ Provide client server function

Widely applicable

Machining center

Lathe

Grinding machine

Drilling/milling machine

Manipulator

Conveyor

Automatic monitoring of the use of important parts of the machine

Crash protection video

Our business has been distributed all over the world

By contracting from conception to turnkey, we can provide you with a complete set of service procedures: conception, actual installation, operation commissioning, technical training, production optimization and big data required by industrial 4.0!

COUNT FOR MORE

Please leave your contact information and our customer manager will contact you as soon as possible

COUNT FOR MORE

Please leave your contact information and our customer manager will contact you as soon as possible

Contact us

Hotline

400-828-3830

E-mail

Sales@wimisoft.com

-

Official account

Official account

Copyright © 2021 MasterLink All Rights Reserved.

苏ICP备19005118号-1

Product trial