Flexible management system (FMS) of production lines

Flexible Manufacturing System (FMS) is an automated manufacturing system composed of CNC processing equipment, material storage and transportation devices and computer control systems

Flexible management system (FMS) of production lines

Flexible Manufacturing System (FMS) is an automated manufacturing system composed of CNC processing equipment, material storage and transportation devices and computer control systems

Home / Flexible management system (FMS) of production lines

FMS System Description

Definition of FMS

Flexible manufacturing system (FMS) is an automatic manufacturing system composed of CNC processing equipment, material storage and transportation equipment and computer control system. It includes multiple flexible manufacturing cells, which can be rapidly adjusted according to the changes of manufacturing tasks or production, and is suitable for multi variety and small batch production.

Functions of FMS

√ It can automatically control and manage the processing process of parts, including automatic control of manufacturing quality, automatic diagnosis and processing of faults, and automatic collection and processing of manufacturing information;

√ Multiple parts of a part family can be manufactured through simple software system changes;

√ Automatically control and manage the transportation and storage process of materials (including workpieces and tools);

√ It can solve the mixed flow processing of parts under multiple machine tools without additional costs;

FMS Features

● High equipment utilization

● Reduce equipment investment

● Reduce floor space

● Reduce direct labor costs

● Reduce the number of WIP and shorten the production preparation time

● Have rapid response capability

● Maintain strong production capacity

● High and stable product quality

● High flexibility of system operation

● Good adaptability to output change

● Facilitate factory automation

● High investment, long development cycle and high management level

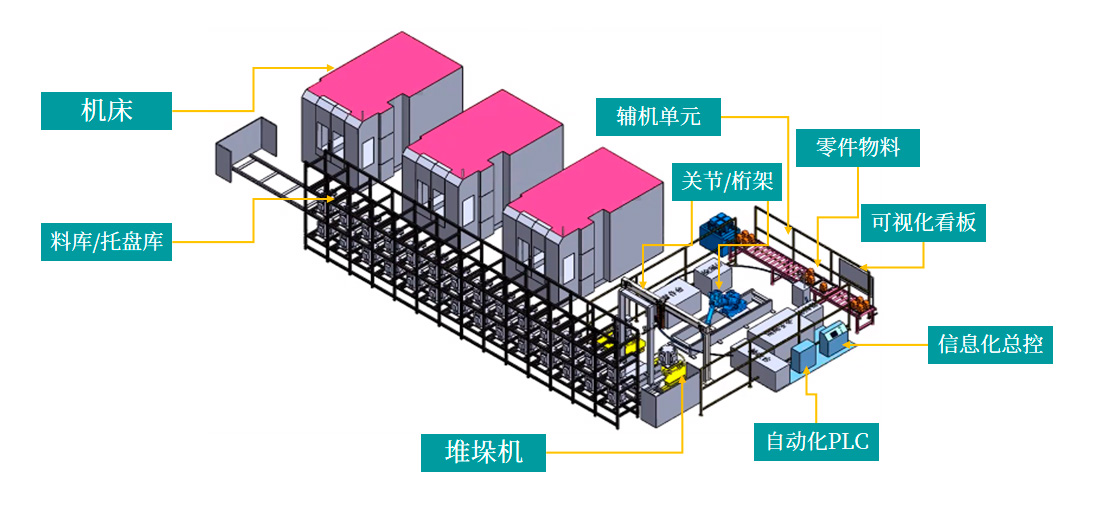

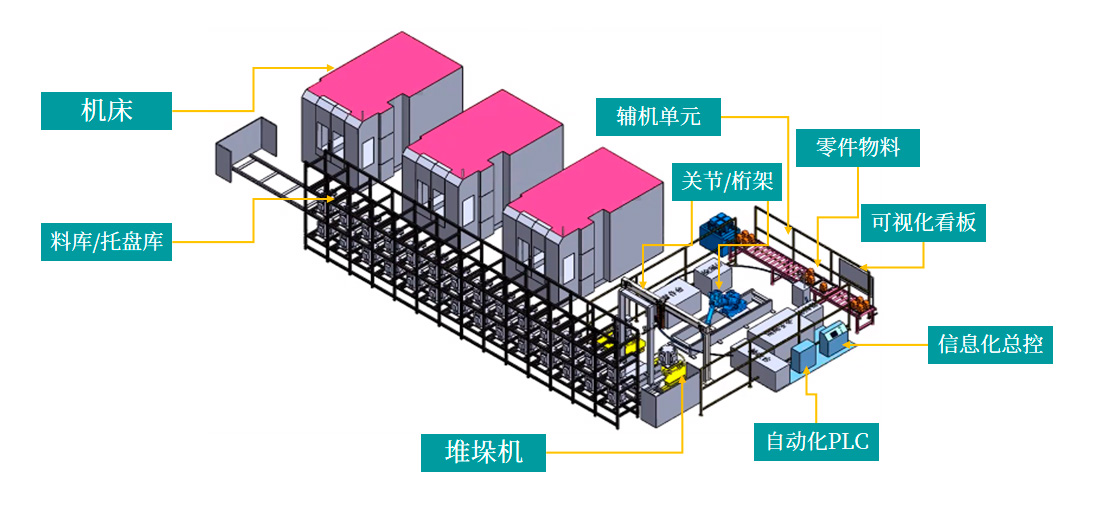

FMS production line composition

Small batch, multi variety, flexible and unmanned

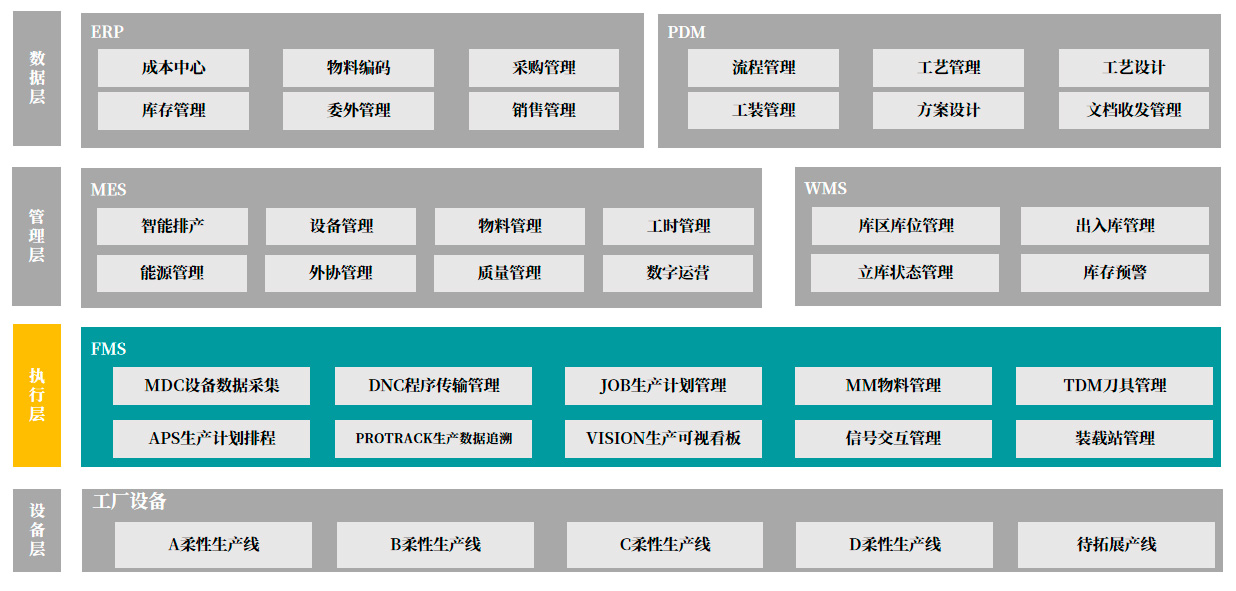

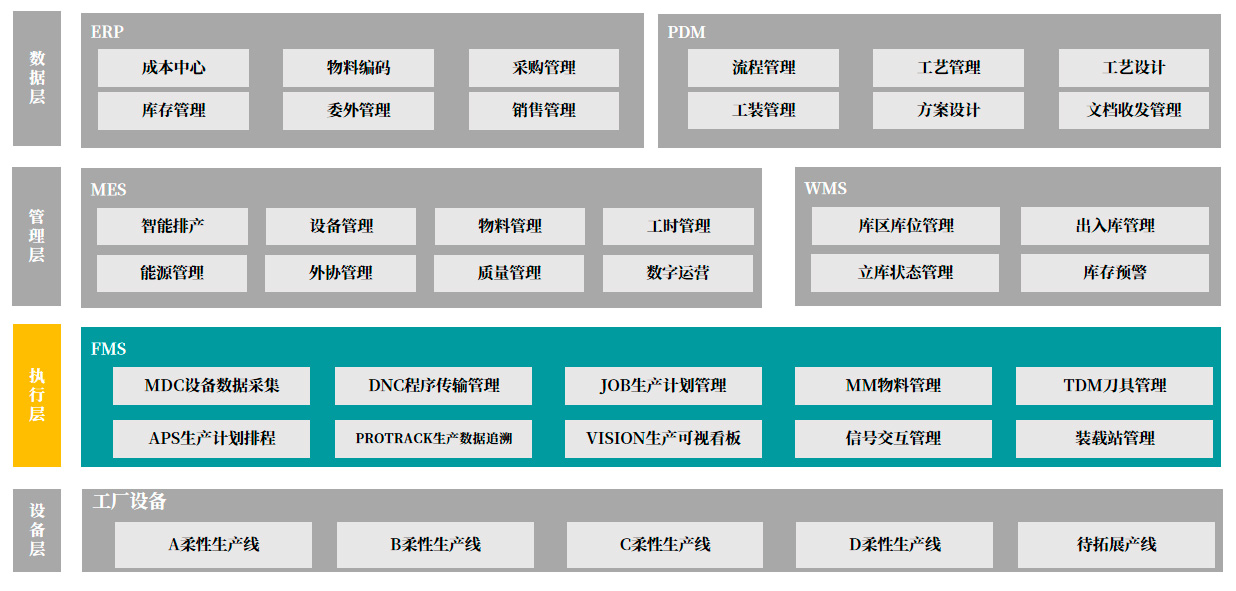

Intelligent factory information architecture

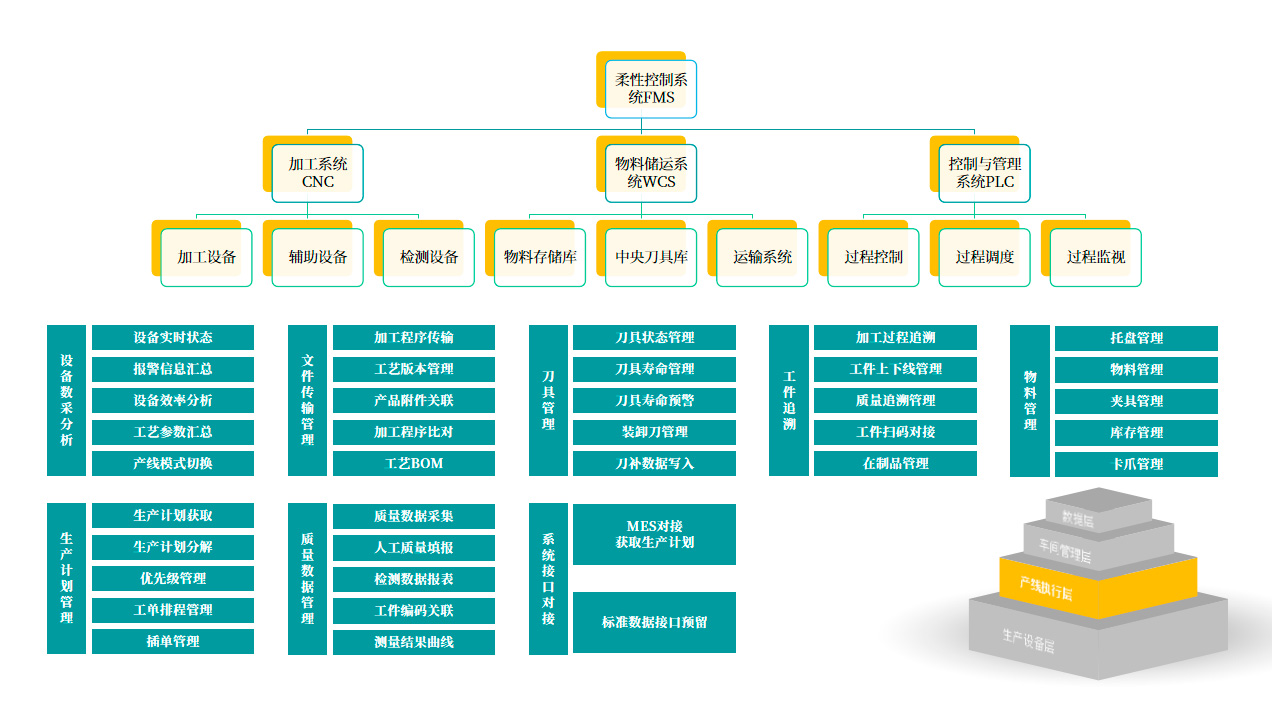

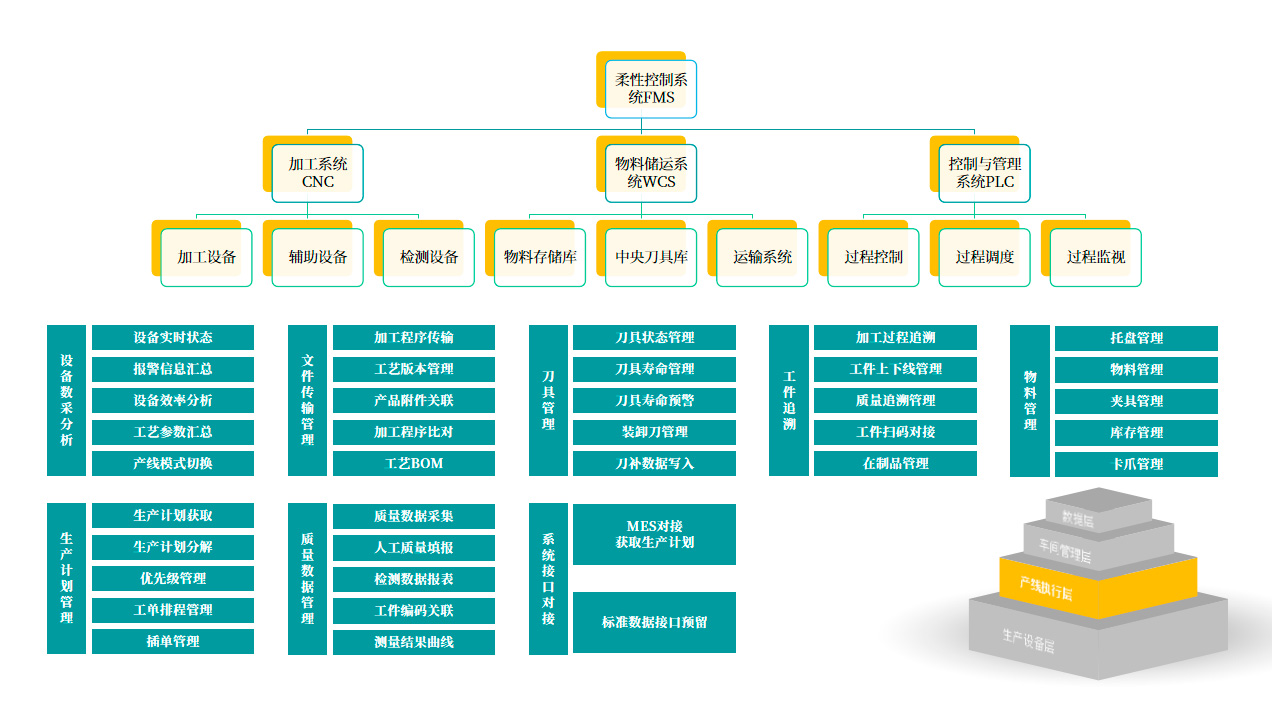

FMS system function module

Main execution interface of software

Production line display

● Intelligentization: support mixed line processing of multiple products

● Automation: control the machine tool to deliver the workpiece type as required and select the corresponding processing program

● Informatization: real-time monitoring of equipment status, warehouse location, loading station status and tool life

● Process oriented: real-time display of processing status and work order execution

● Integration: can interface with the third party's upper system

FMS System Description

Definition of FMS

Flexible manufacturing system (FMS) is an automatic manufacturing system composed of CNC processing equipment, material storage and transportation equipment and computer control system. It includes multiple flexible manufacturing cells, which can be rapidly adjusted according to the changes of manufacturing tasks or production, and is suitable for multi variety and small batch production.

Functions of FMS

√ It can automatically control and manage the processing process of parts, including automatic control of manufacturing quality, automatic diagnosis and processing of faults, and automatic collection and processing of manufacturing information;

√ Multiple parts of a part family can be manufactured through simple software system changes;

√ Automatically control and manage the transportation and storage process of materials (including workpieces and tools);

√ It can solve the mixed flow processing of parts under multiple machine tools without additional costs;

FMS Features

● High equipment utilization

● Reduce equipment investment

● Reduce floor space

● Reduce direct labor costs

● Reduce the number of WIP and shorten the production preparation time

● Have rapid response capability

● Maintain strong production capacity

● High and stable product quality

● High flexibility of system operation

● Good adaptability to output change

● Facilitate factory automation

● High investment, long development cycle and high management level

FMS production line composition

Small batch, multi variety, flexible and unmanned

Intelligent factory information architecture

FMS system function module

Main execution interface of software

Production line display

● Intelligentization: support mixed line processing of multiple products

● Automation: control the machine tool to deliver the workpiece type as required and select the corresponding processing program

● Informatization: real-time monitoring of equipment status, warehouse location, loading station status and tool life

● Process oriented: real-time display of processing status and work order execution

● Integration: can interface with the third party's upper system

COUNT FOR MORE

Please leave your contact information and our customer manager will contact you as soon as possible

COUNT FOR MORE

Please leave your contact information and our customer manager will contact you as soon as possible

Contact us

Hotline

400-828-3830

E-mail

Sales@wimisoft.com

-

Official account

Official account

Copyright © 2021 MasterLink All Rights Reserved.

苏ICP备19005118号-1

Product trial