Machine diagnostics/Conditionmonitoring

A Necessary Mechanical Dynamic Diagnostic Tool for Precision Machine Tool Manufacturers

Machine diagnostics/Conditionmonitoring

A Necessary Mechanical Dynamic Diagnostic Tool for Precision Machine Tool Manufacturers

Home / Portable machine tool diagnostic instrument

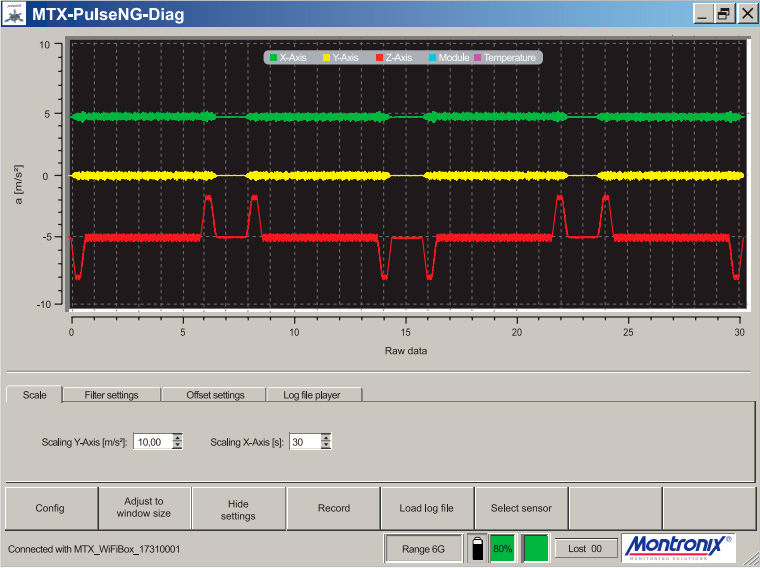

Portable diagnostic instrument WiFi BoxNG

■ Have you ever had problems such as poor machining quality and abnormal machine operation?

■ Is the possible cause a fault, wear, damage or incorrect installation?

■ Our WiFi BoxNG system can help you identify and locate these problems!

Wireless data transmission

◆Real time measurement is possible even in a closed machining space

Portable installation and use

◆Not limited by the working position and environment

Preventive equipment maintenance

◆Identify the problem as early as possible

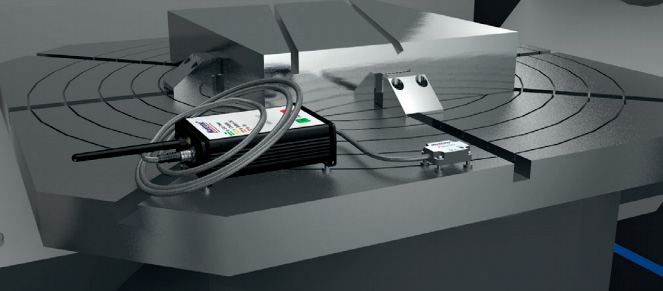

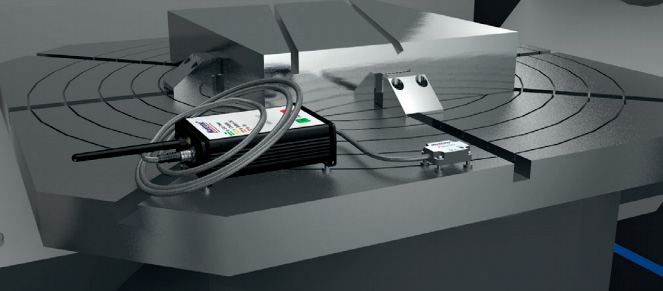

■ Installation Example

The installation and removal of WiFi BoxNG is easier and more convenient by using a strong magnet.

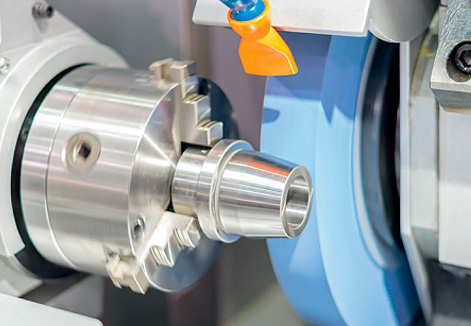

Spindle box

Workbench/carriage

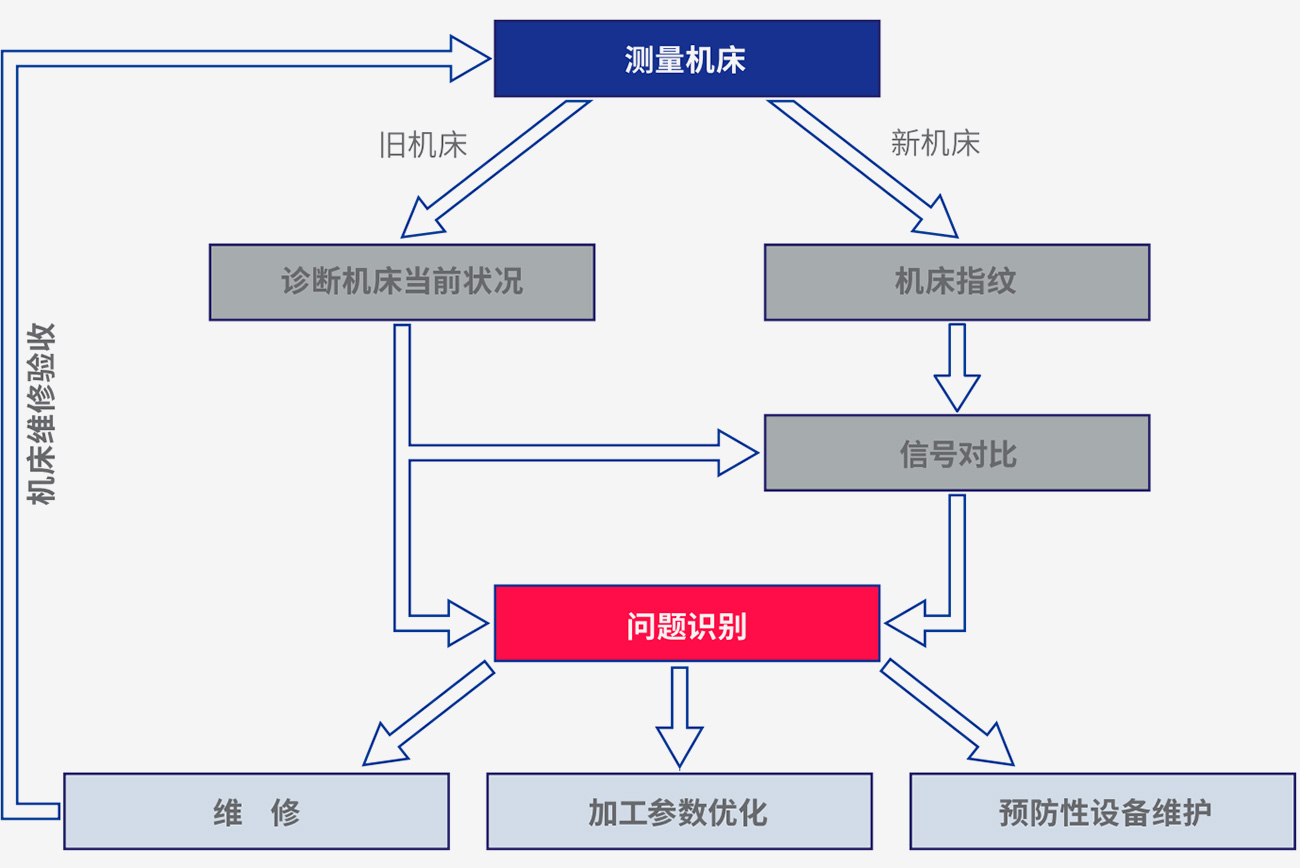

Application examples

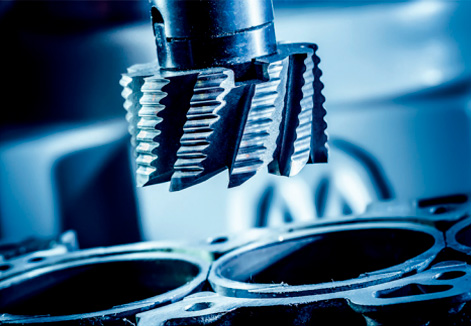

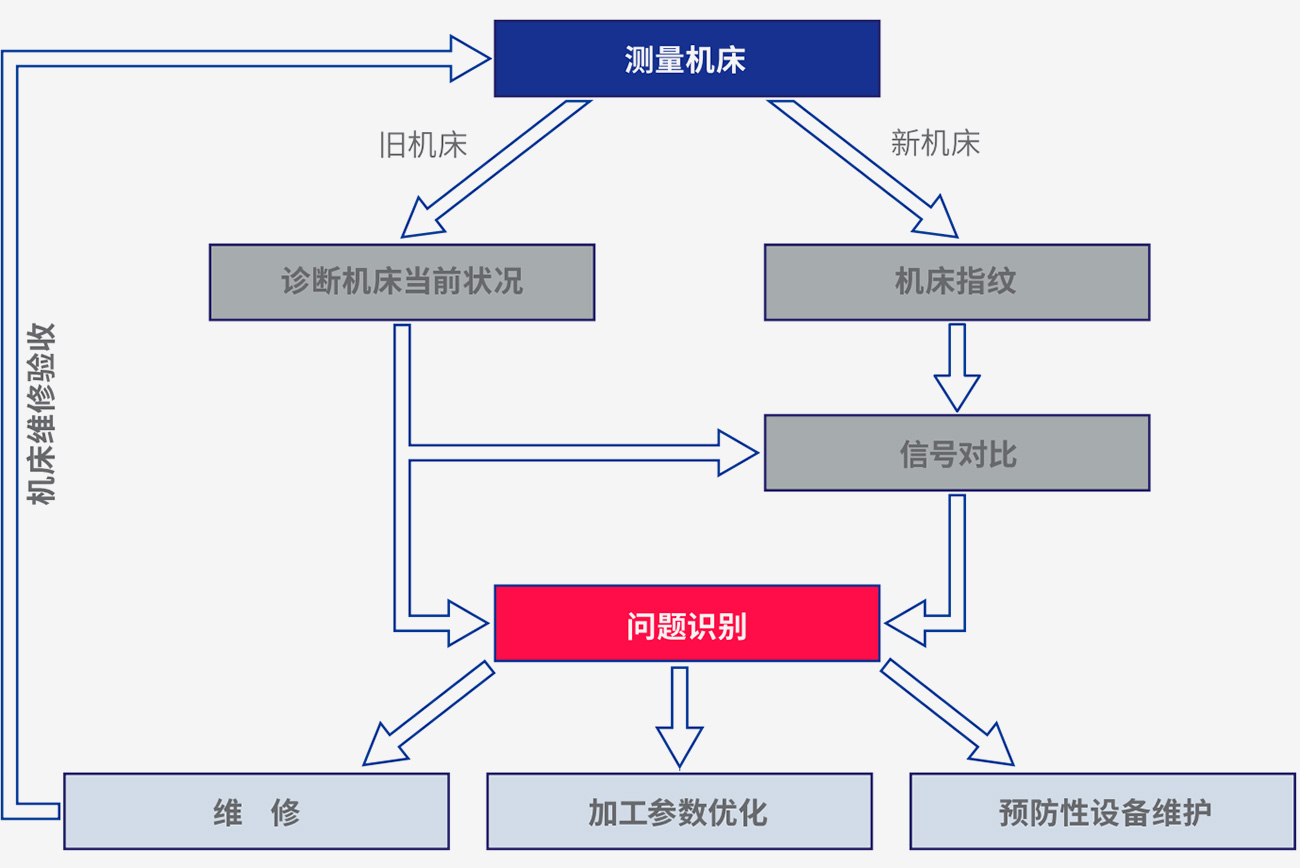

■ Machining process optimization

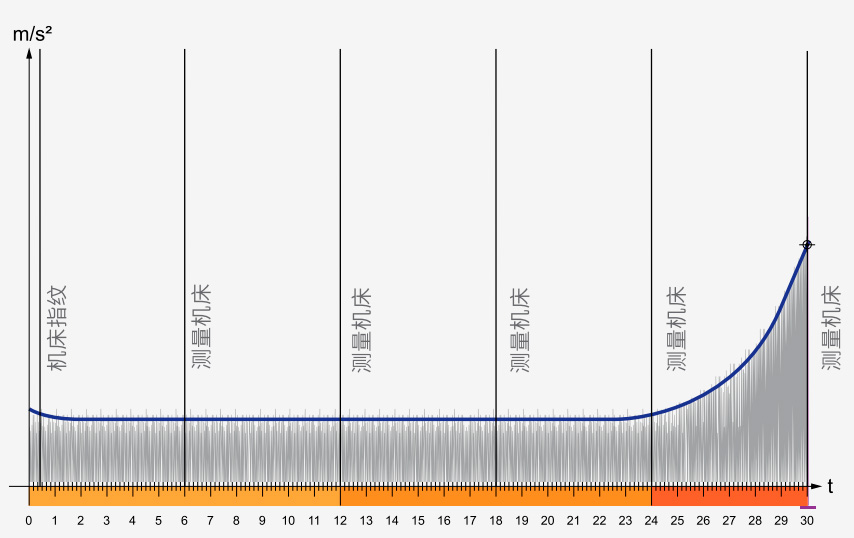

■ Periodic measurement

Application case

Recognize problems of machine tool parts

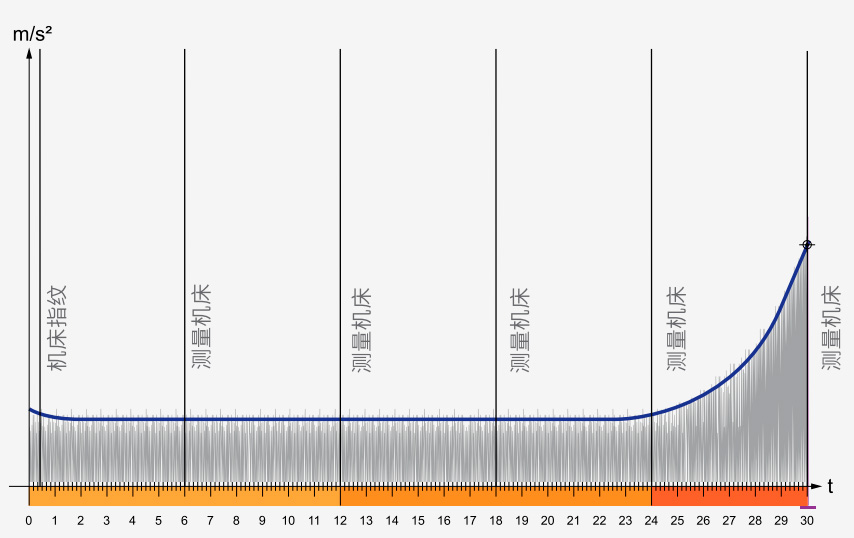

■Wear trend

■Damage

■Rigidity error

■Insufficient clamping force

Benefit from WiFi BoxNG

■Improve the usage rate of equipment

■Repair result acceptance

■Extend the service life of tools

■Optimization of machining parameters

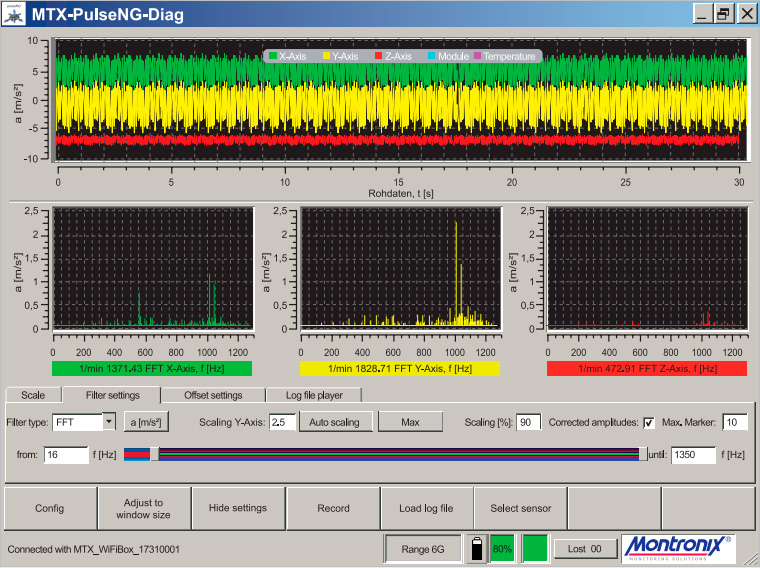

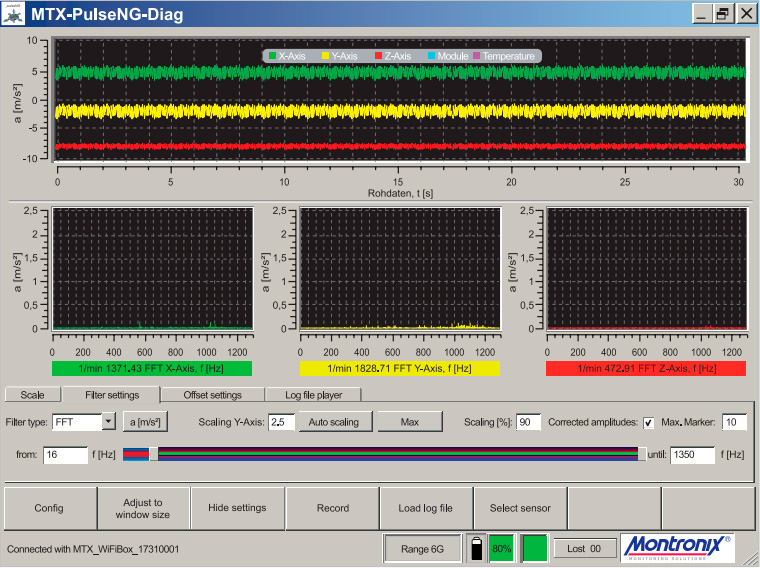

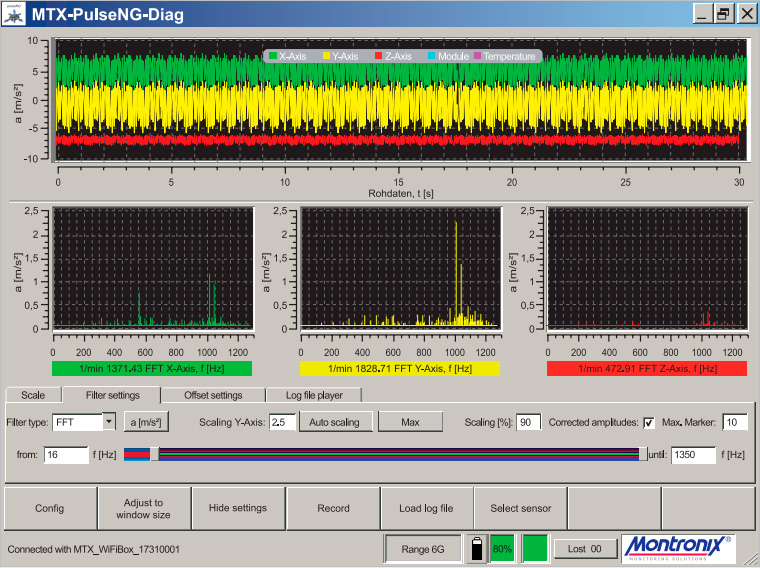

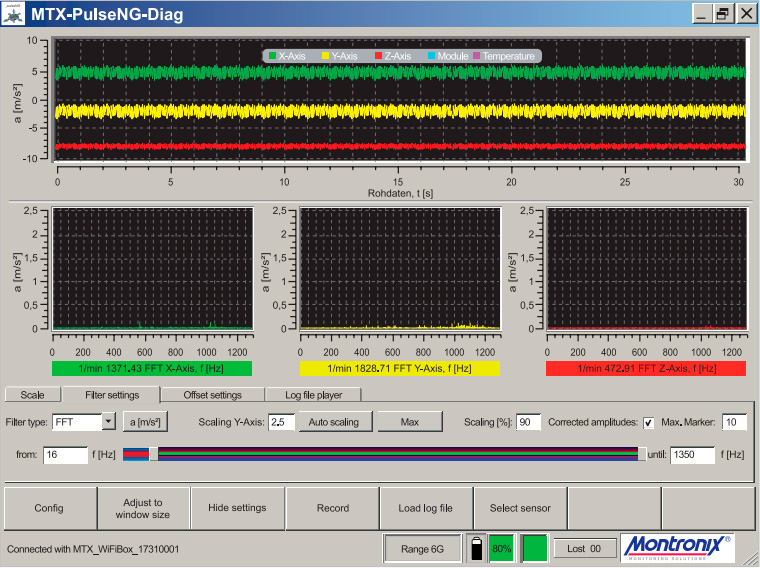

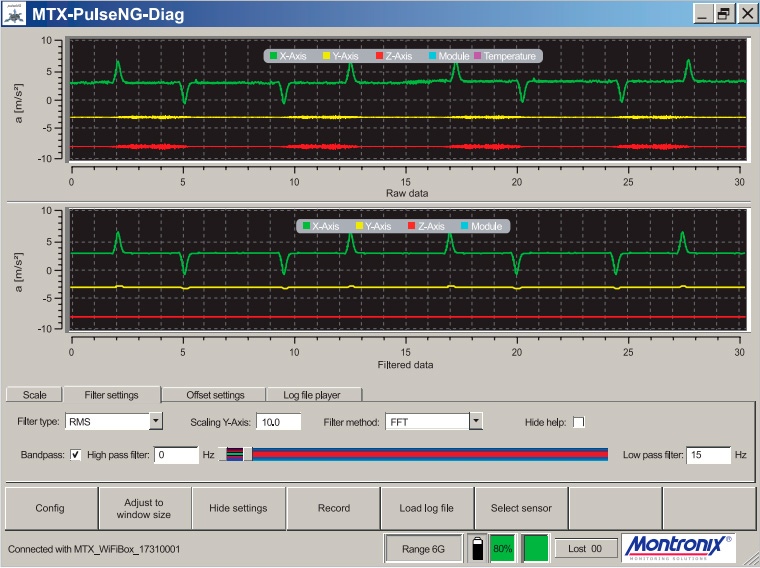

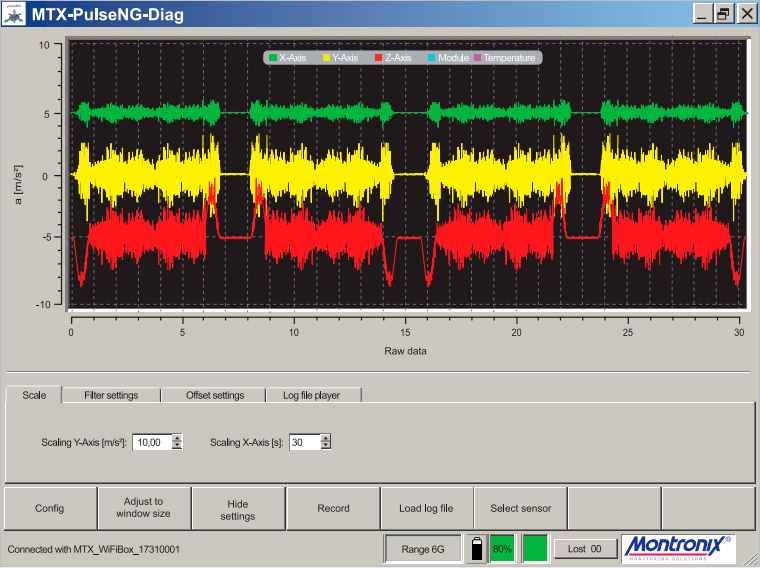

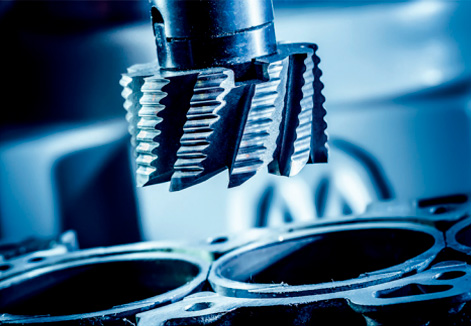

■ Spindle

Before improvement

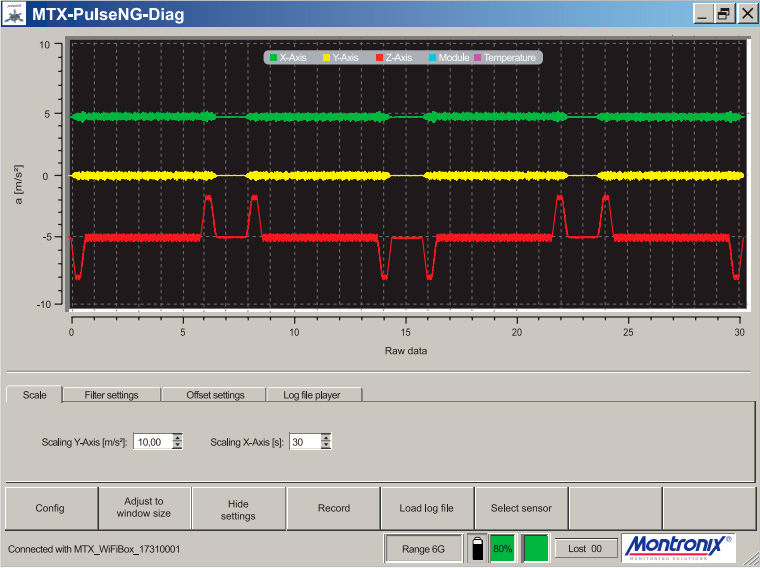

After improvement

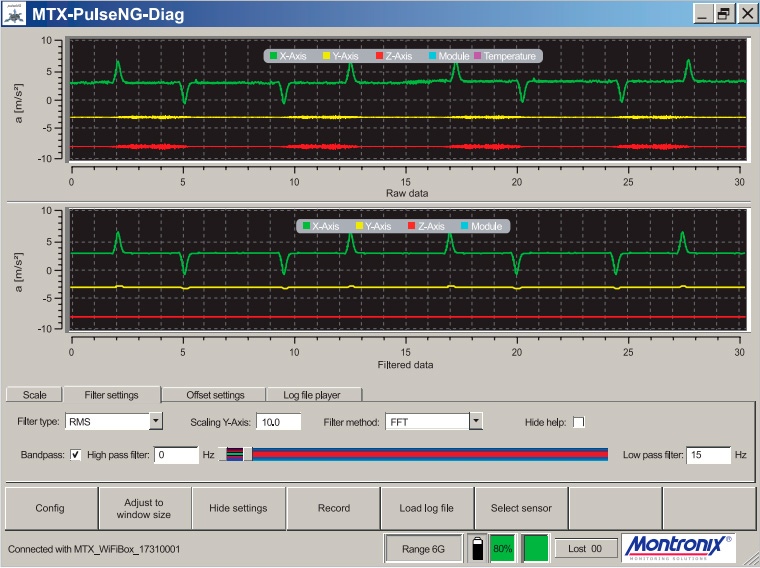

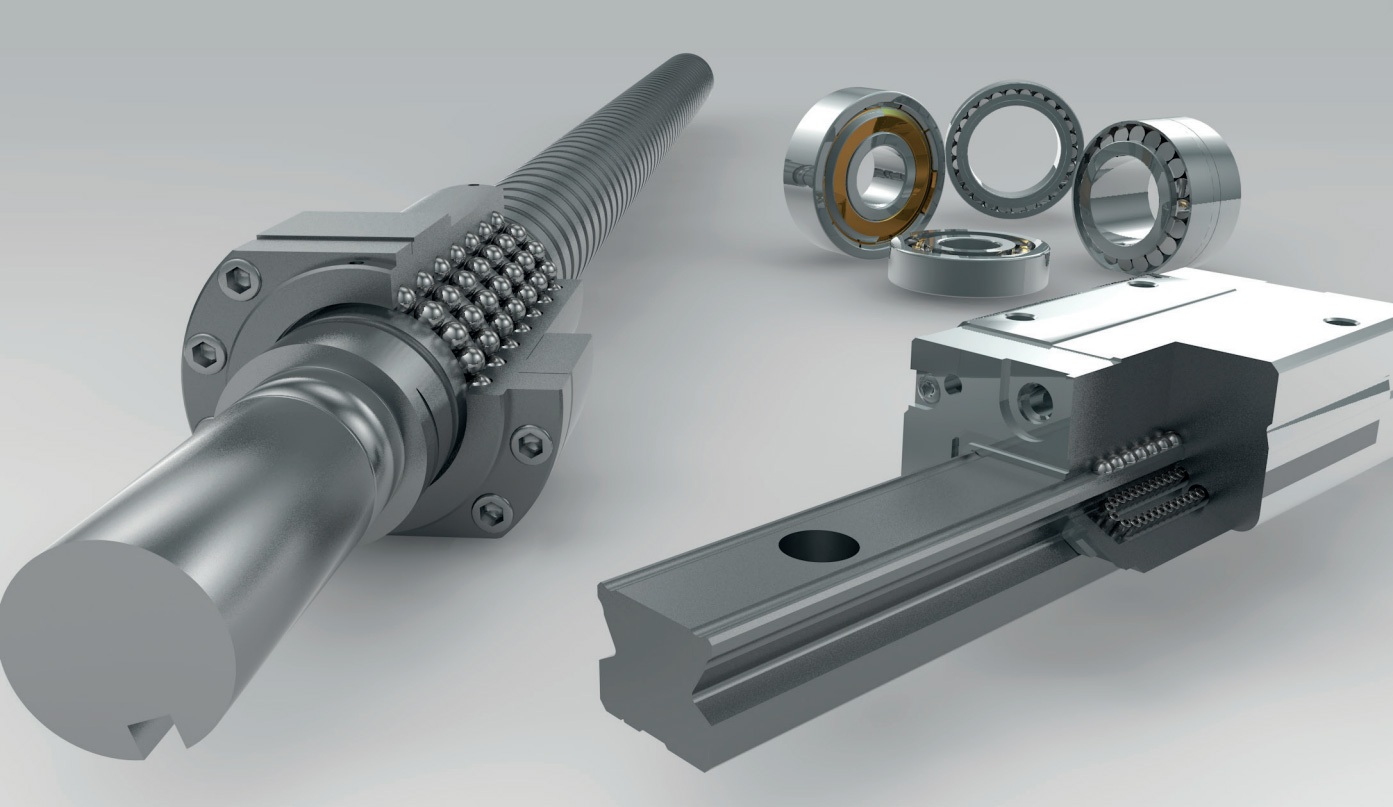

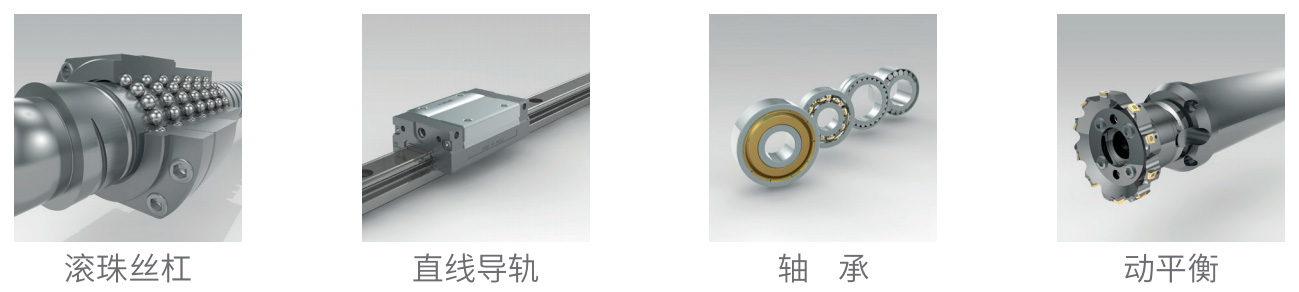

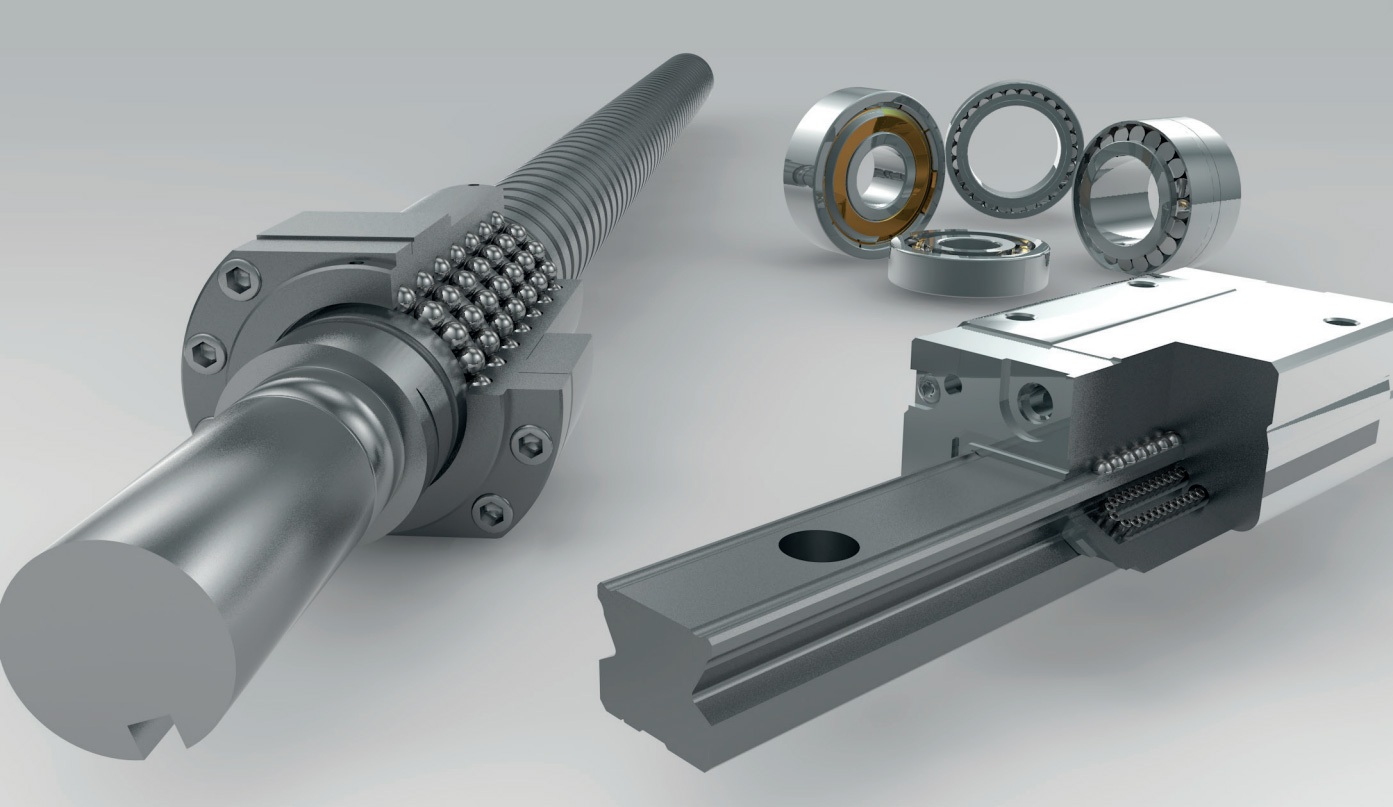

■ Ball screw

Before improvement

After improvement

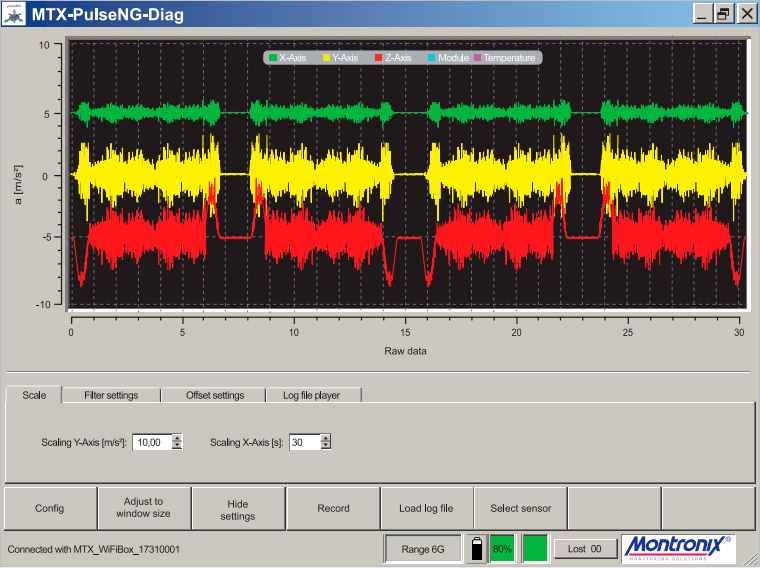

■ Linear guide rail / sliding rail

Before improvement

After improvement

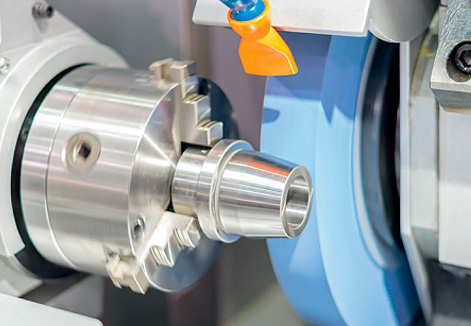

Wide application

■ Machining process optimization

Machining center

Lathe

grinder

Miller / driller

Manipulator

Transmission device

Machine tool part diagnosis

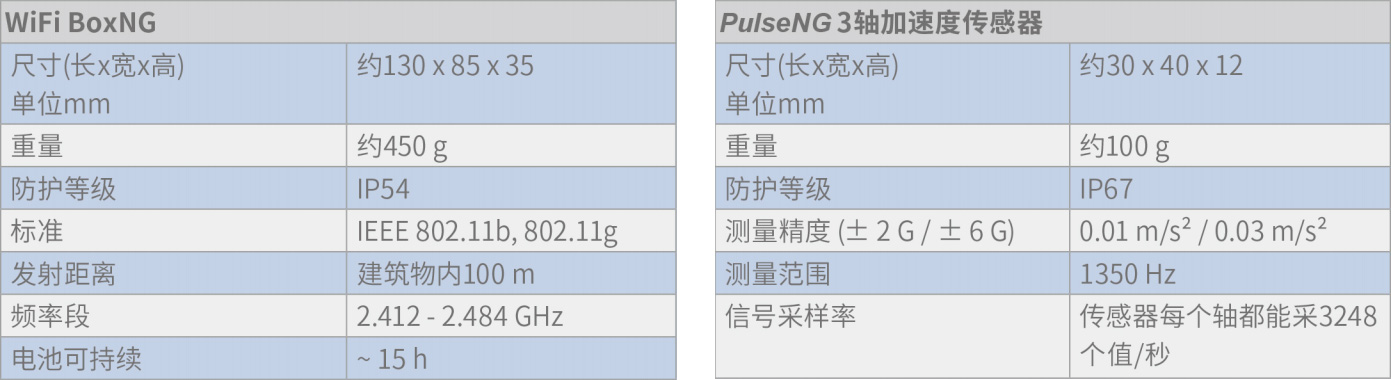

Product performance

■ Our business has been distributed all over the world

Portable diagnostic instrument WiFi BoxNG

■ Have you ever had problems such as poor machining quality and abnormal machine operation?

■ Is the possible cause a fault, wear, damage or incorrect installation?

■ Our WiFi BoxNG system can help you identify and locate these problems!

Wireless data transmission

◆Real time measurement is possible even in a closed machining space

Portable installation and use

◆Not limited by the working position and environment

Preventive equipment maintenance

◆Identify the problem as early as possible

■ Installation Example

The installation and removal of WiFi BoxNG is easier and more convenient by using a strong magnet.

Spindle box

Workbench/carriage

Application examples

■ Machining process optimization

■ Periodic measurement

Application case

Recognize problems of machine tool parts

■Wear trend

■Damage

■Rigidity error

■Insufficient clamping force

Benefit from WiFi BoxNG

■Improve the usage rate of equipment

■Repair result acceptance

■Extend the service life of tools

■Optimization of machining parameters

■ Spindle

Before improvement

After improvement

■ Ball screw

Before improvement

After improvement

■ Linear guide rail / sliding rail

Before improvement

After improvement

Wide application

■ Machining process optimization

Machining center

Lathe

grinder

Miller / driller

Manipulator

Transmission device

Machine tool part diagnosis

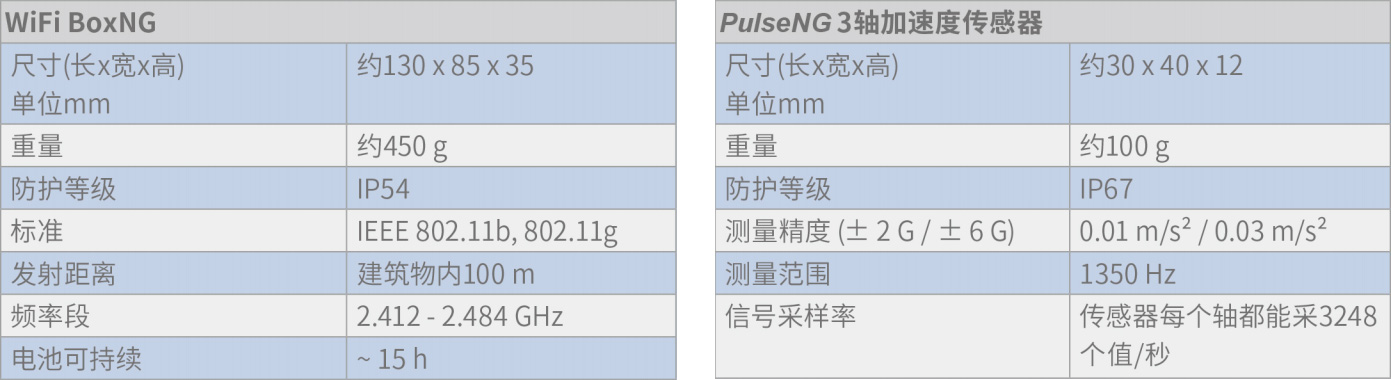

Product performance

■ Our business has been distributed all over the world

COUNT FOR MORE

Please leave your contact information and our customer manager will contact you as soon as possible

COUNT FOR MORE

Please leave your contact information and our customer manager will contact you as soon as possible

Contact us

Hotline

400-828-3830

E-mail

Sales@wimisoft.com

-

Official account

Official account

Copyright © 2021 MasterLink All Rights Reserved.

苏ICP备19005118号-1

Product trial