Intelligent management system (LMS) of production lines

The intelligent management system of LMS production line realizes intelligent production line through management software

Intelligent management system (LMS) of production lines

The intelligent management system of LMS production line realizes intelligent production line through management software

Home / Intelligent management system (LMS) of production lines

Common problems of automatic production lines

The production line information is not transparent, and the efficiency is low

● The line and equipment efficiency is unknown.

● The idle and waiting time are too long.

● Abnormal alarms are not solved timely.

● The line yield abnormality cannot be accessed timely, and there is a decision-making delay.

● The material waiting time is too long.

The production line abnormality cost is too high

● Tools are not replaced timely.

● Equipment is not maintained timely.

● CPK is instable and cannot be positioned accurately.

● The quality is instable, and the spot check frequency is not flexible.

Production line management & control is not continued

● The production line management & control loop cannot be formed.

● The production statistics & analysis is difficult.

● Data statistics is interrupted

Paper-based management

● Paper-based process and quality documents.

● Documents are easy to damage.

● Data timeliness is poor.

Quality cannot be tracked

● The utilization rate of quality data is not high.

● It is hard to form quality archives.

● It is hard to realize quality tracing.

● There are no offline alarms for parts.

Difficult information sharing

● Information isolated island.

● Actively access key information.

● The accuracy is hard to guarantee.

Common problems of automatic production lines

The production line information is not transparent, and the efficiency is low

● The line and equipment efficiency is unknown.

● The idle and waiting time are too long.

● Abnormal alarms are not solved timely.

● The line yield abnormality cannot be accessed timely, and there is a decision-making delay.

● The material waiting time is too long.

The production line abnormality cost is too high

● Tools are not replaced timely.

● Equipment is not maintained timely.

● CPK is instable and cannot be positioned accurately.

● The quality is instable, and the spot check frequency is not flexible.

Production line management & control is not continued

● The production line management & control loop cannot be formed.

● The production statistics & analysis is difficult.

● Data statistics is interrupted

Paper-based management

Paper-based process and quality documents.

● Documents are easy to damage.

● Data timeliness is poor.

Quality cannot be tracked

● The utilization rate of quality data is not high.

● It is hard to form quality archives.

● It is hard to realize quality tracing.

● There are no offline alarms for parts.

Difficult information sharing

● Information isolated island.

● Actively access key information.

● The accuracy is hard to guarantee.

Product function

LMS production line intelligent management system can realize intelligent management of production lines with the management software to solve problems such as multiple kinds but small batches of production lines, flexible production, non-transparent information, low efficiency, abnormally high cost of production lines, interrupted production line management & control, failure to track quality, paper-based management, difficulty in information sharing, etc.

LMS functions

MDC data statistics and analysis

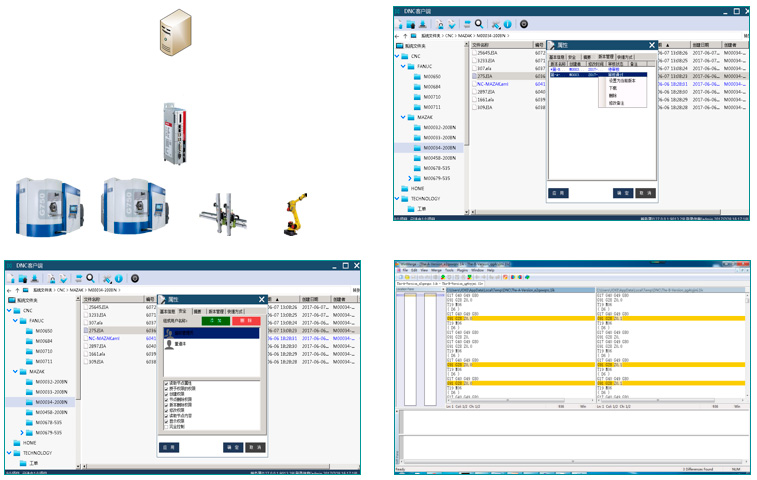

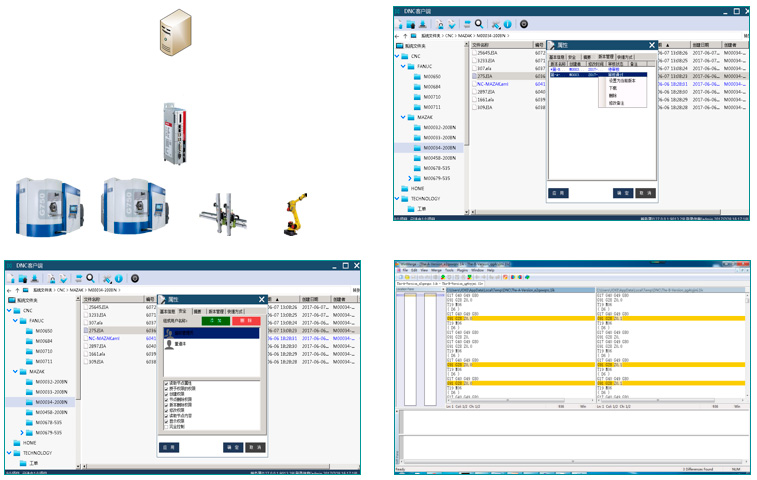

DNC program transmission management

TDM tool management

JOB production schedule management

VISION visual production board

PROTRACK production data tracing

QC quality management

Energy consumption management

Product function

LMS production line intelligent management system can realize intelligent management of production lines with the management software to solve problems such as multiple kinds but small batches of production lines, flexible production, non-transparent information, low efficiency, abnormally high cost of production lines, interrupted production line management & control, failure to track quality, paper-based management, difficulty in information sharing, etc.

LMS functions

MDC data statistics and analysis

DNC program transmission management

TDM tool management

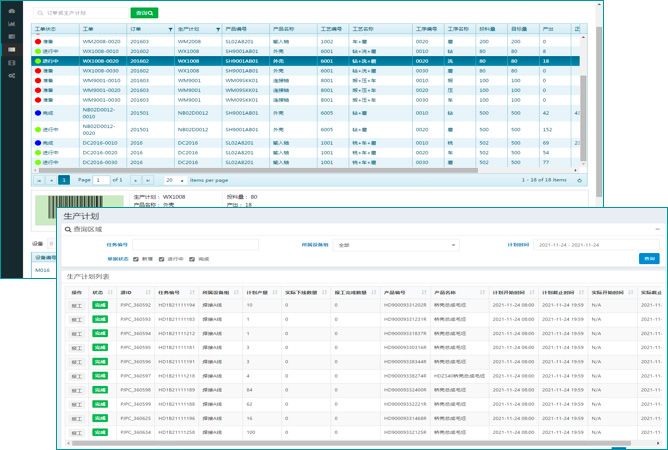

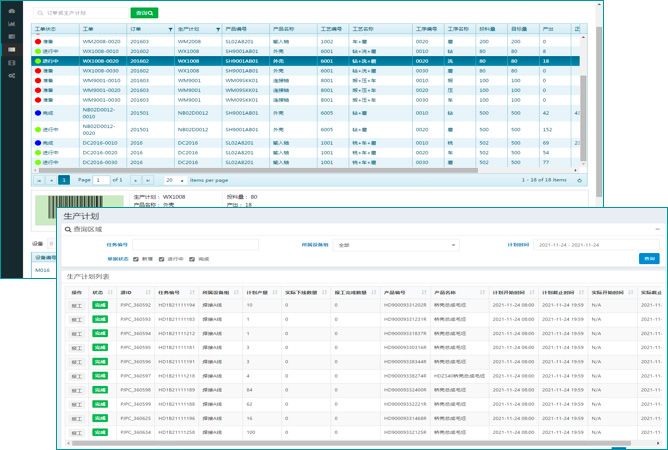

JOB production schedule management

VISION visual production board

PROTRACK production data tracing

QC quality management

Energy consumption management

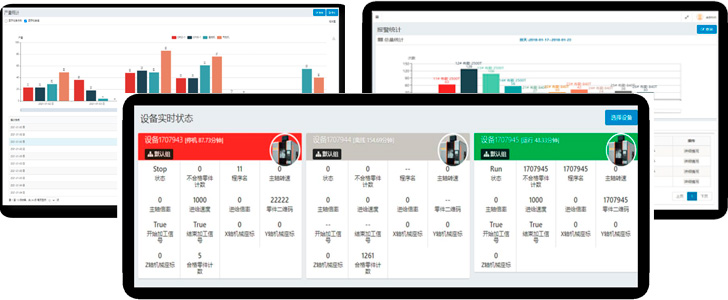

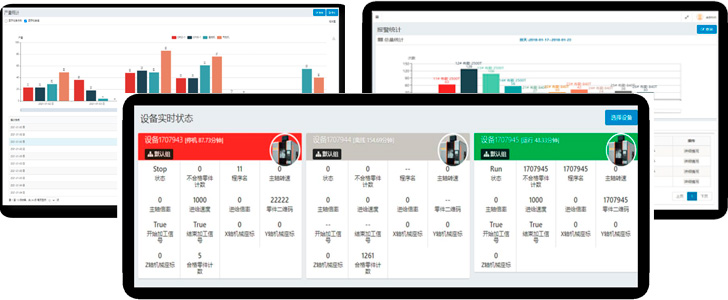

MDC - data statistics and analysis

Overview of the production line state

● Facilitate the person in charge of production lines to control the production line state and adjust the pace of production lines.

Equipment data statistics and display

● Collect data about distribution of the operation time of each set of equipment per day and learn about the utilization rate, idle rate and fault rate of equipment.

Equipment lap installation management

● Enable feedback and search of the shutdown reason and duration to reduce shutdown and waste, and promptly notify the abnormality information.

MDC - data statistics and analysis

Overview of the production line state

● Facilitate the person in charge of production lines to control the production line state and adjust the pace of production lines.

Equipment data statistics and display

● Collect data about distribution of the operation time of each set of equipment per day and learn about the utilization rate, idle rate and fault rate of equipment.

Equipment lap installation management

● Enable feedback and search of the shutdown reason and duration to reduce shutdown and waste, and promptly notify the abnormality information.

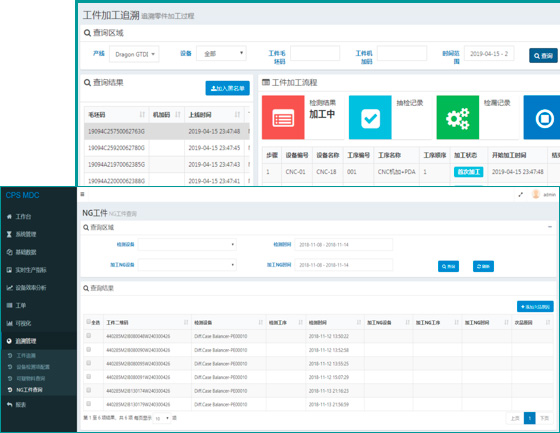

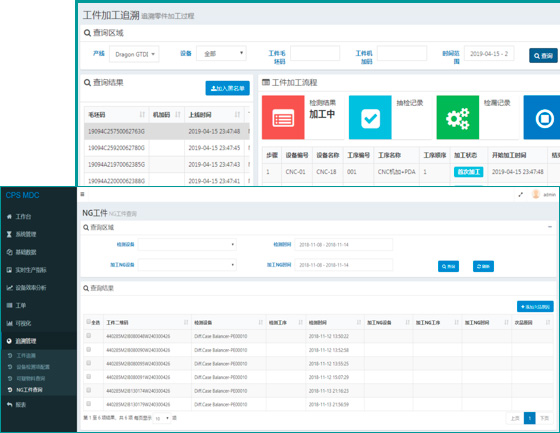

Protrace - production tracing management

Production process tracing

● The system enables inquiry of production process parameters of parts in the production line based on the part identification or code to facilitate tracing of non-conforming parts;

● The corresponding production link can be traced according to abnormal products, and then the corresponding equipment can be provided with shutdown maintenance and servicing to guarantee the conformity of subsequent production with requirements;

● The workpiece list can be inquired and screened according to the state of workpieces defined in the system, such as spot check or not, NG or not, etc.

Protrace - production tracing management

Production process tracing

● The system enables inquiry of production process parameters of parts in the production line based on the part identification or code to facilitate tracing of non-conforming parts;

● The corresponding production link can be traced according to abnormal products, and then the corresponding equipment can be provided with shutdown maintenance and servicing to guarantee the conformity of subsequent production with requirements;

● The workpiece list can be inquired and screened according to the state of workpieces defined in the system, such as spot check or not, NG or not, etc.

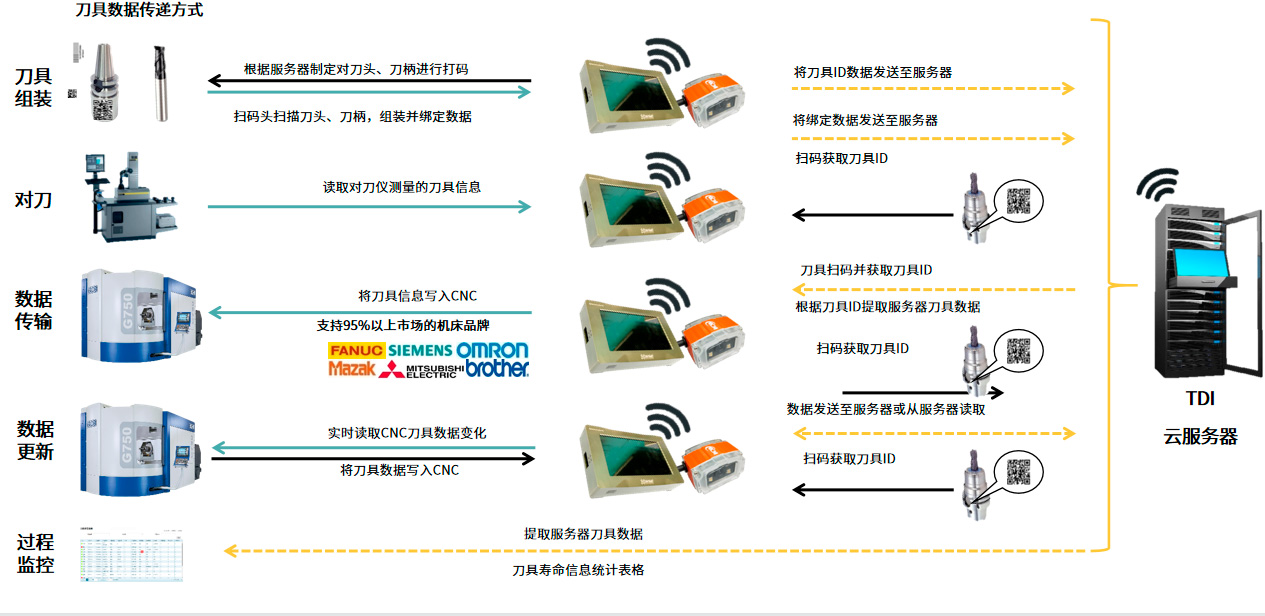

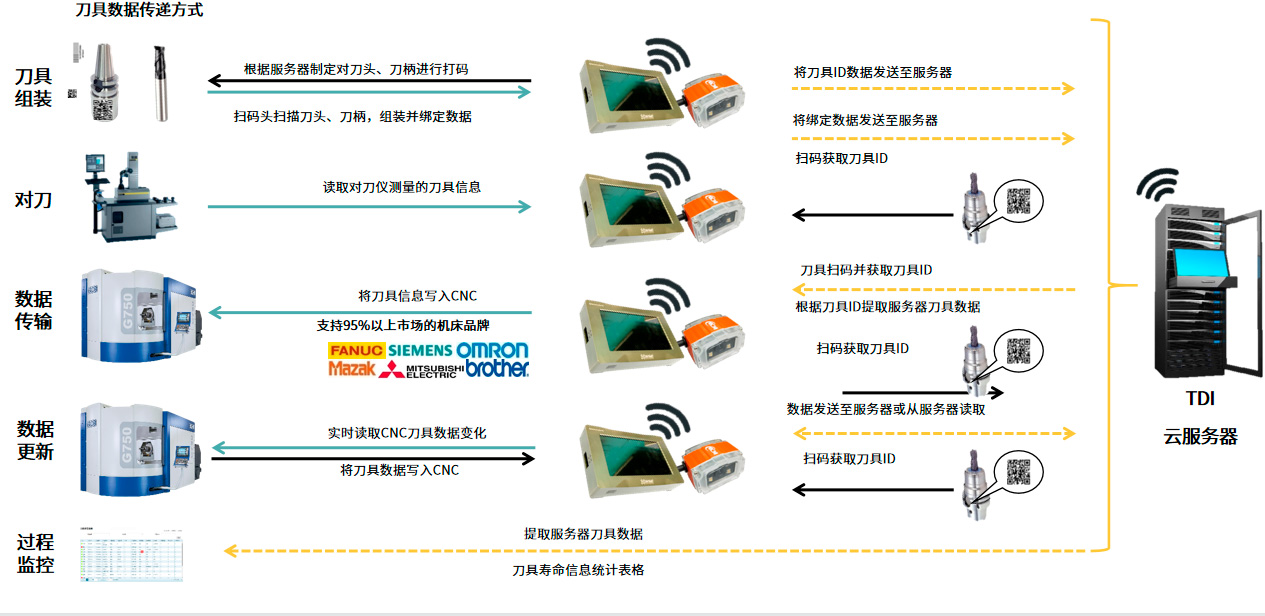

TDM - tool management

TDM - tool management

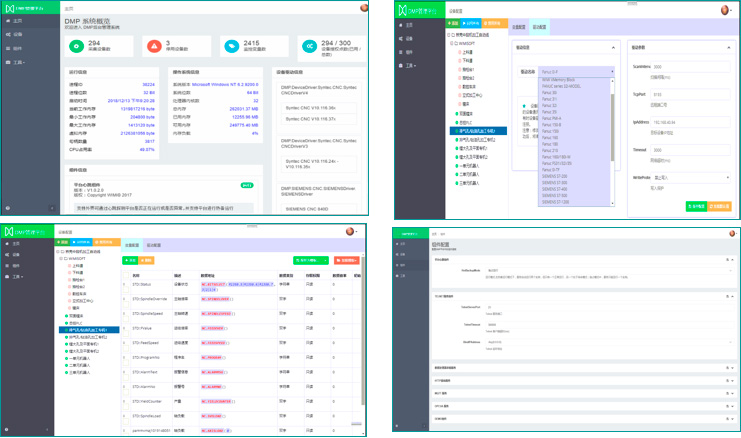

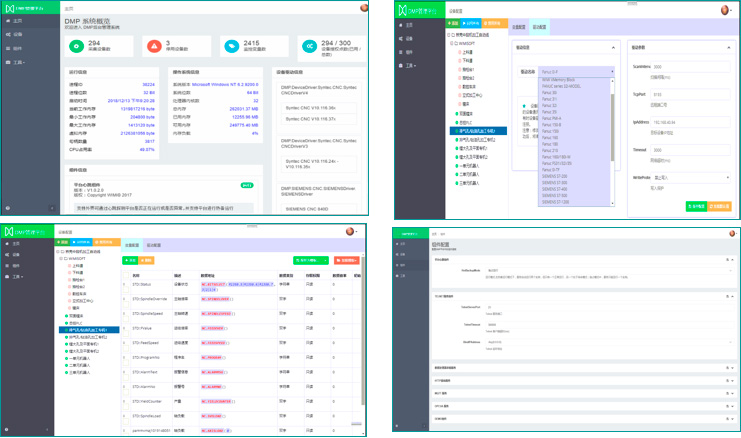

DMP acquisition platform

DMP acquisition platform

Basic data

● Support the access of various kinds of heterogeneous devices to the DMP platform;

● Support the access of various upper-level systems to equipment data via standard protocols (OPCUA, MQTT, WebAPI, etc.);

● Support the platform to be configured with various data items and equipment communication parameters in a dynamic manner; provide online tools and facilitate authentication data and platform functions;

● Support secondary development, enable the user to develop various functional components to extend functions of DMP and realize the self-defined logic.

Basic data

● Support the access of various kinds of heterogeneous devices to the DMP platform;

● Support the access of various upper-level systems to equipment data via standard protocols (OPCUA, MQTT, WebAPI, etc.);

● Support the platform to be configured with various data items and equipment communication parameters in a dynamic manner; provide online tools and facilitate authentication data and platform functions;

● Support secondary development, enable the user to develop various functional components to extend functions of DMP and realize the self-defined logic.

DNC program transmission management

Process procedure management

● Allocate the corresponding part number to production line equipment, and compare with the equipment to invoke the corresponding subprogram;

● Judge the scheduling dispatch and invoking execution according to the part process flow through the maintenance process path and associated process documents.

● Program uploading and downloading

● Program version management

● Program approval process

● Program comparison

DNC program transmission management

Process procedure management

● Allocate the corresponding part number to production line equipment, and compare with the equipment to invoke the corresponding subprogram;

● Judge the scheduling dispatch and invoking execution according to the part process flow through the maintenance process path and associated process documents.

● Program uploading and downloading

● Program version management

● Program approval process

● Program comparison

PMS - personnel management

Personnel online performance management

● The personnel management system records the online and offline operation logs of personnel as well as the working situation of personnel;

● The personnel management system binds the equipment production work order task completion result with the equipment operator to facilitate performance assessment of production personnel.

PMS - personnel management

Personnel online performance management

● The personnel management system records the online and offline operation logs of personnel as well as the working situation of personnel;

● The personnel management system binds the equipment production work order task completion result with the equipment operator to facilitate performance assessment of production personnel.

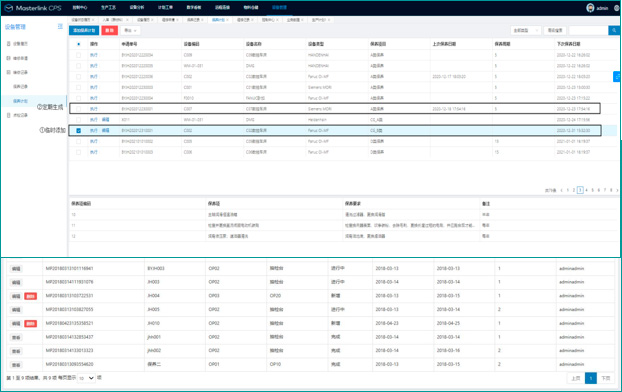

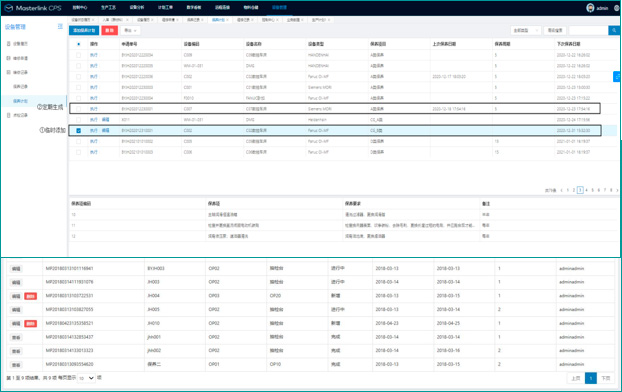

JOB - production work order management

Production work order management

● Production work order management can realize submission of the production schedule of production lines, and collect parameters and the equipment situation in the production process to facilitate tracing of the work order;

● According to the equipment parameters of the bound MO, it is convenient to follow the production of each part in the production order and find the fault point;

● The production plan can be manually reported and supplemented with relevant information;

● It can also interface with AGV and WMS systems for AGV trolley calling and WMS material warehousing application.

JOB - production work order management

Production work order management

● Production work order management can realize submission of the production schedule of production lines, and collect parameters and the equipment situation in the production process to facilitate tracing of the work order;

● According to the equipment parameters of the bound MO, it is convenient to follow the production of each part in the production order and find the fault point;

● The production plan can be manually reported and supplemented with relevant information;

● It can also interface with AGV and WMS systems for AGV trolley calling and WMS material warehousing application.

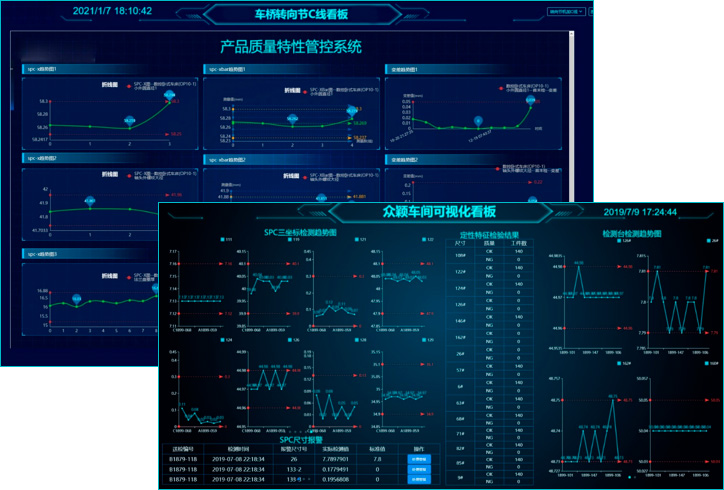

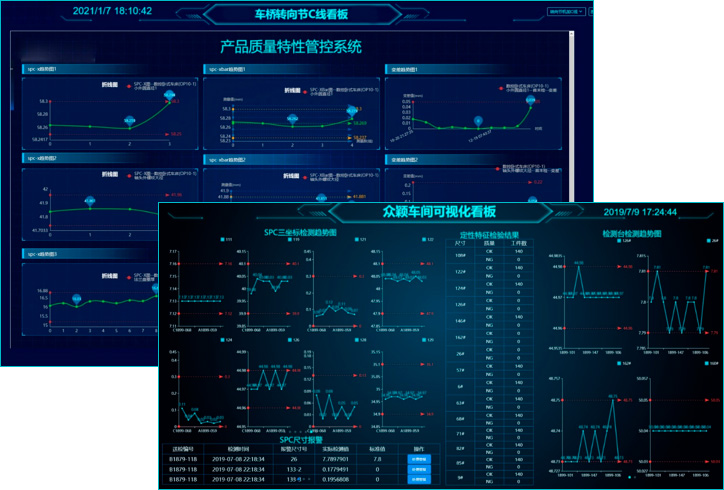

SPC Production Quality Management

Production quality management

● Connect the measuring equipment in the production line - CMM, etc. to obtain the part measurement data;

● Sample the test data, customize and develop the test data analysis trend chart according to customer needs.

SPC Production Quality Management

Production quality management

● Connect the measuring equipment in the production line - CMM, etc. to obtain the part measurement data;

● Sample the test data, customize and develop the test data analysis trend chart according to customer needs.

TPM - Production Equipment Management

Equipment maintenance management

● Regularly generate maintenance items for the same type of equipment according to the set maintenance items or create a separate maintenance plan based on the equipment, select equipment codes, maintain maintenance items, implement maintenance plans, and generate maintenance documents;

● Production line equipment management can record equipment maintenance logs, understand equipment maintenance process, and trace non production consumables of equipment.

TPM - Production Equipment Management

Equipment maintenance management

● Regularly generate maintenance items for the same type of equipment according to the set maintenance items or create a separate maintenance plan based on the equipment, select equipment codes, maintain maintenance items, implement maintenance plans, and generate maintenance documents;

● Production line equipment management can record equipment maintenance logs, understand equipment maintenance process, and trace non production consumables of equipment.

Production energy consumption management

Production energy consumption monitoring

● Data monitoring variables can be customized to monitor the energy use of plant equipment in real time, and corresponding energy consumption plans and indicators can be specified according to the statistical analysis results;

● Energy consumption monitoring, energy consumption statistics, and energy consumption analysis. The real-time energy consumption related data of each equipment can be viewed in real time, the statistical results can be summarized and displayed in various styles, and the analysis results can be displayed in charts.

Production energy consumption management

Production energy consumption monitoring

● Data monitoring variables can be customized to monitor the energy use of plant equipment in real time, and corresponding energy consumption plans and indicators can be specified according to the statistical analysis results;

● Energy consumption monitoring, energy consumption statistics, and energy consumption analysis. The real-time energy consumption related data of each equipment can be viewed in real time, the statistical results can be summarized and displayed in various styles, and the analysis results can be displayed in charts.

VISION - Production Kanban Display

Production monitoring platform

● The production monitoring platform can collect and display the equipment status, production efficiency, equipment alarm information, production line output and other information of the whole production line;

● It is convenient for the person in charge of the production line to control the production line status and adjust the production line rhythm;

● Advantages of visualization platform: drag and drop component development, which can quickly build a visual interface.

VISION - Production Kanban Display

Production monitoring platform

● The production monitoring platform can collect and display the equipment status, production efficiency, equipment alarm information, production line output and other information of the whole production line;

● It is convenient for the person in charge of the production line to control the production line status and adjust the production line rhythm;

● Advantages of visualization platform: drag and drop component development, which can quickly build a visual interface.

Why choose us?

Rich project experience

It has implemented intelligent management software (including FMS software) for nearly 500 production lines, and has rich project experience.

Strong professional ability

The company gathers elites in the industry and has rich work

Experience. Software programmers, CNC, PLC equipment system testers, on-site implementers, and hardware R&D personnel all have more than 7 years of work experience and independently develop professional software products.

Fast technology update

The company has continuously increased its research and development and investment in new technologies, purchased different PLC and CNC simulators, developed data acquisition methods, followed the pace of market system updates, and constantly improved its technical capabilities.

The underlying driving rate is rich and mature

95% CNC control on the market can be linked

The dynamic system and PLC control dynamic system do not need the manufacturer to open the interface.

Why choose us?

Rich project experience

It has implemented intelligent management software (including FMS software) for nearly 500 production lines, and has rich project experience.

Strong professional ability

The company gathers elites in the industry and has rich work

Experience. Software programmers, CNC, PLC equipment system testers, on-site implementers, and hardware R&D personnel all have more than 7 years of work experience and independently develop professional software products.

Fast technology update

The company has continuously increased its research and development and investment in new technologies, purchased different PLC and CNC simulators, developed data acquisition methods, followed the pace of market system updates, and constantly improved its technical capabilities.

The underlying driving rate is rich and mature

95% CNC control on the market can be linked

The dynamic system and PLC control dynamic system do not need the manufacturer to open the interface.

COUNT FOR MORE

Please leave your contact information and our customer manager will contact you as soon as possible

COUNT FOR MORE

Please leave your contact information and our customer manager will contact you as soon as possible

Contact us

Hotline

400-828-3830

E-mail

Sales@wimisoft.com

-

Official account

Official account

Copyright © 2021 MasterLink All Rights Reserved.

苏ICP备19005118号-1

Product trial