Workshop collaborative manufacture management system E-MES

Collaborative manufacturing management system is a comprehensive information management system for workshop executive level of manufacturing enterprises

Workshop Collaborative Manufacturing Management System E-MES

Collaborative manufacturing management system is a comprehensive information management system for workshop executive level of manufacturing enterprises

Home / Workshop collaborative manufacture management system E-MES

What is a collaborative intelligent manufacturing management system

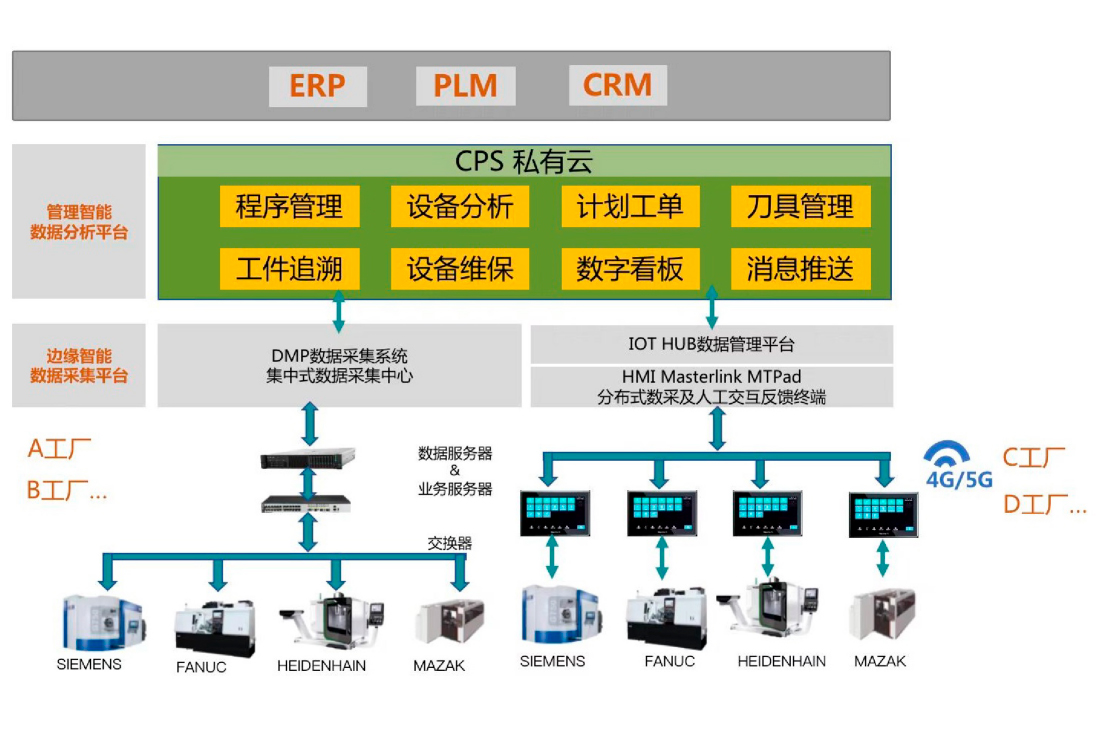

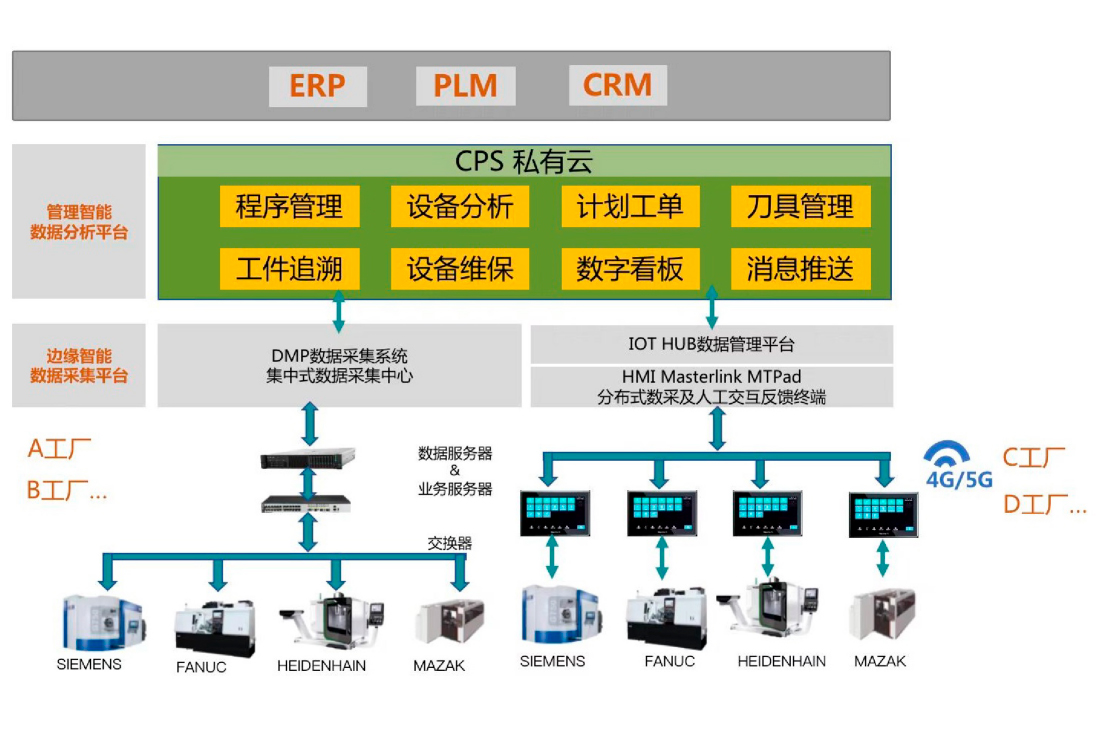

The collaborative manufacturing management system is a comprehensive information management system for the workshop executive level of manufacturing enterprises. Based on the relevant data of human, machine, material, method, environment and measurement, it realizes the collaborative interaction and management of the business level, and realizes digital management and lean production.

Product function module

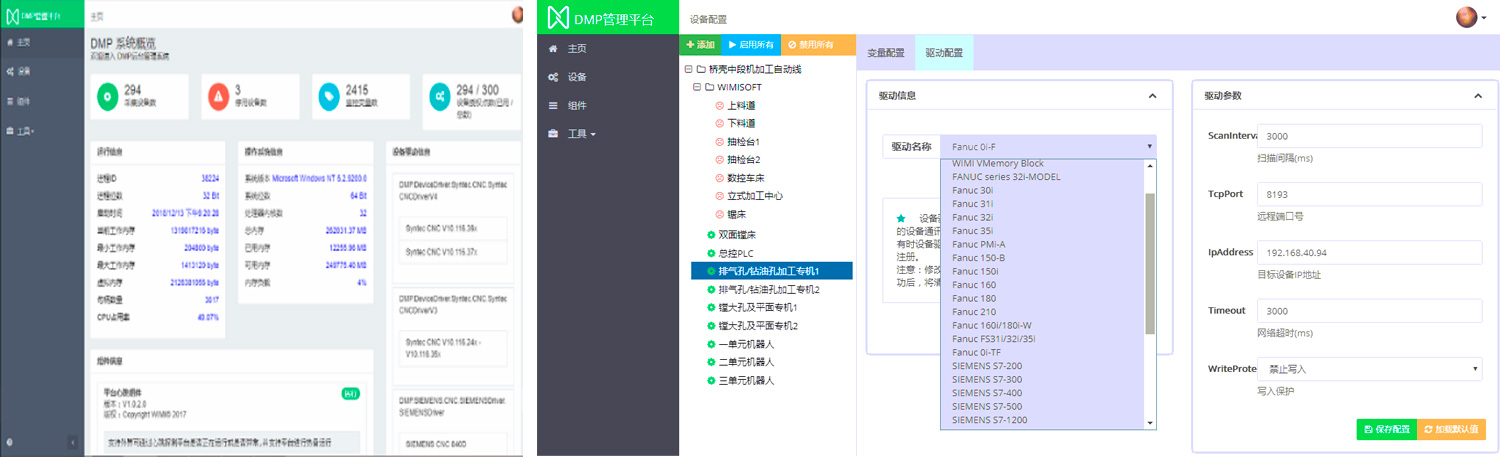

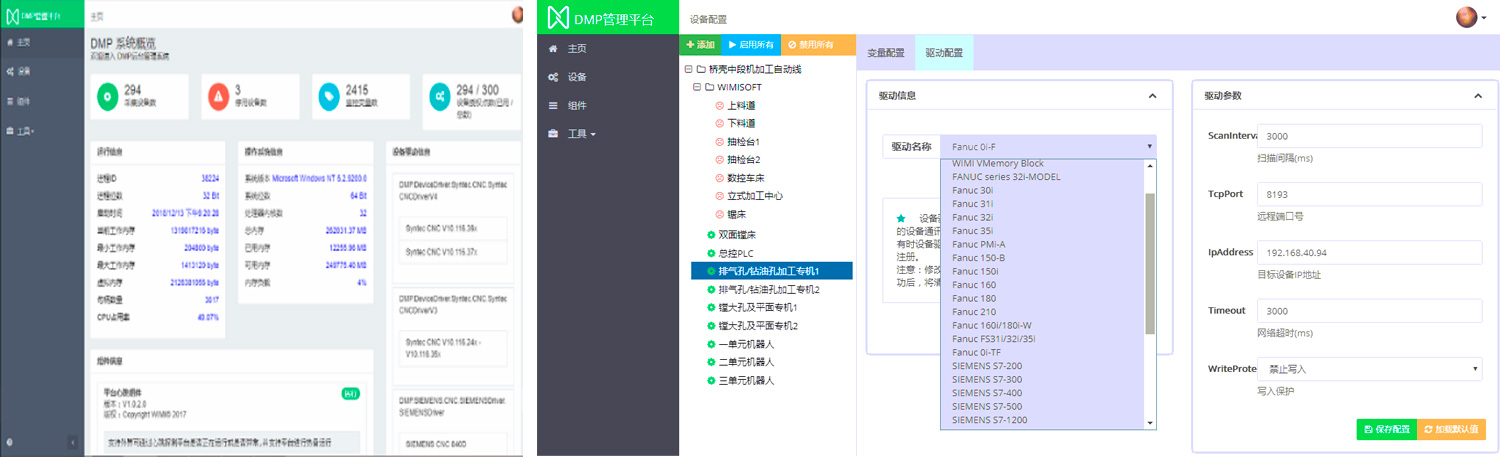

DMP data acquisition platform

● DMP data acquisition platform is compatible with 95% controllers (CNC and PLC) on the market

● DMP acquisition platform can customize the variables and parameters to be collected by the equipment, and configure different acquisition frequencies

● Support secondary development. The user (upper system developer) can develop functional components, expand DMP functions, and realize user-defined logic

● Support multiple interfaces: OPC UA, Web Service, Web API, MQTT

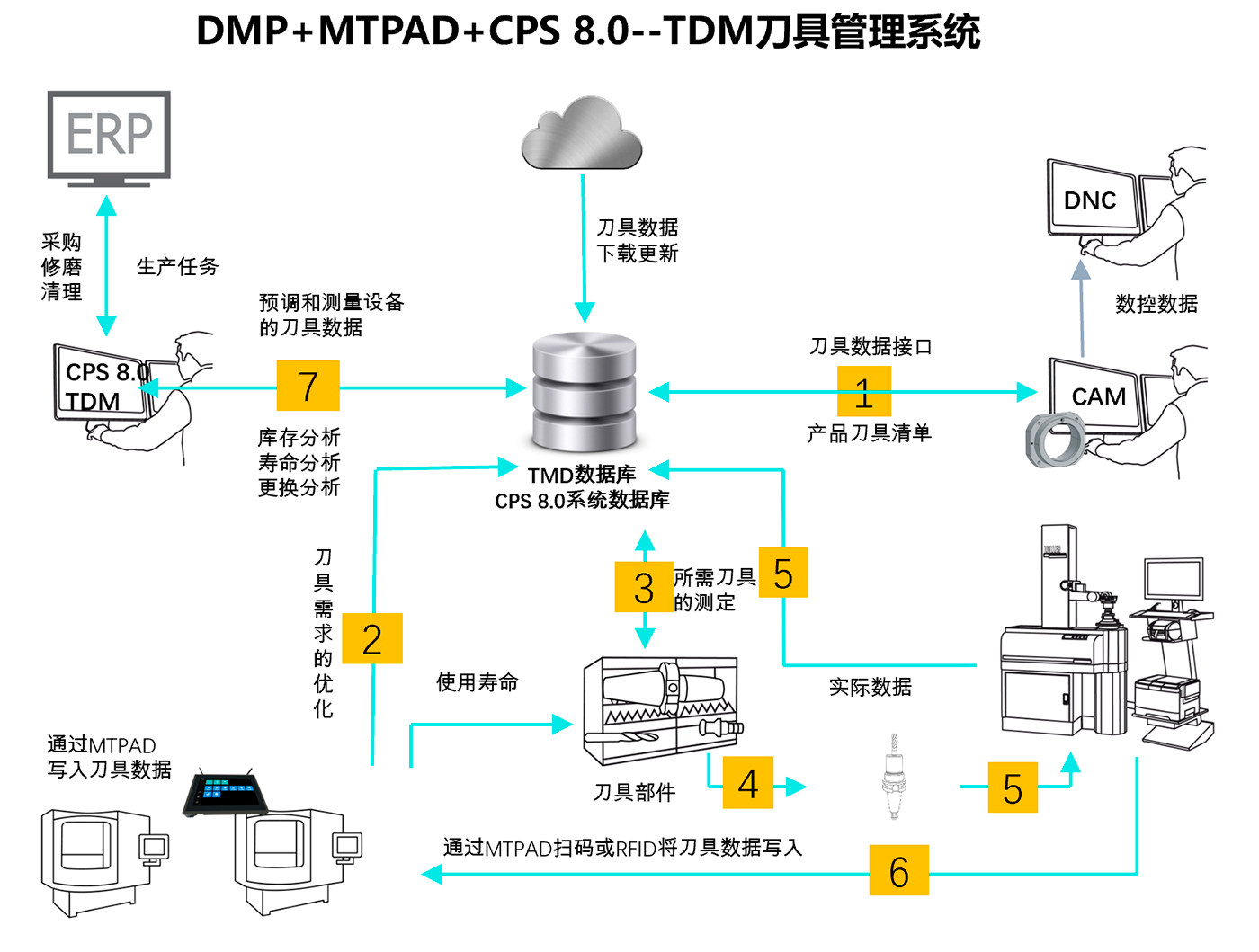

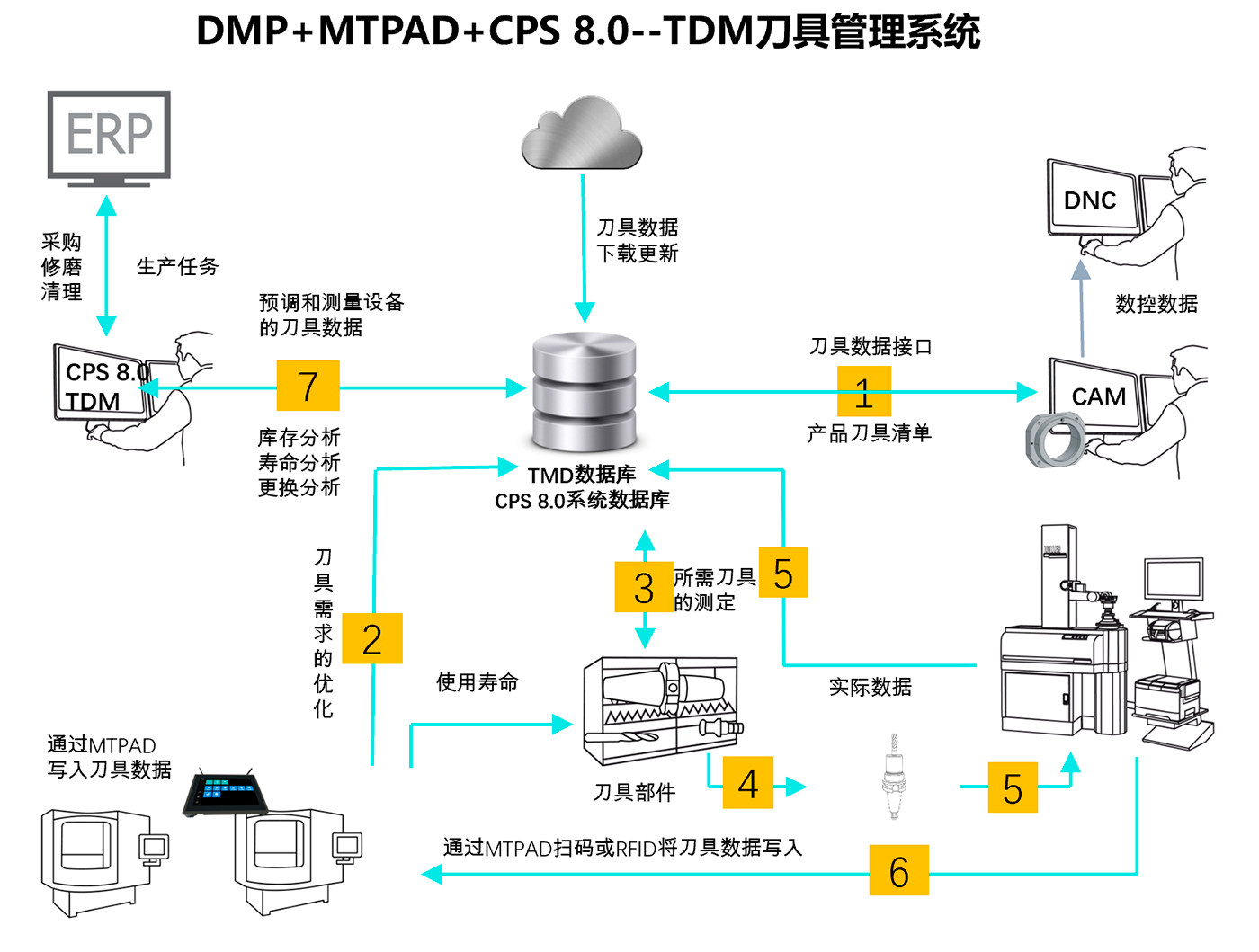

Tool Data Management (TDM)

The TDM tool data management system integrates the independent tool magazine of a single machine tool into the system server by monitoring the tool data of the machine tool in real time, combining the tool inventory management and workpiece production data.

Improve the management efficiency of the whole process of purchasing and warehousing, tool distribution, tool installation, life monitoring, loss and scrap in the production process

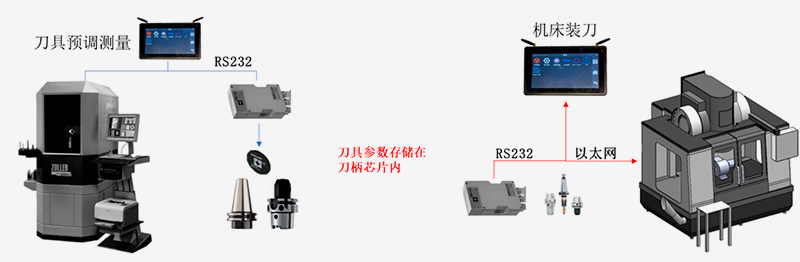

Scheme I 2D code scheme of tool holder

Function description: the software system stores the 2D code of tool holder and tool measurement data in association

Implementation method:

Workflow: (This scheme needs to configure servers and deploy local area networks)

1. Tool measurement, generating measurement data

2. HMI reads measurement data, manually scans 2D code of tool handle, and server binds tool measurement data

3. The HMI on the machine tool side scans the 2D code of the tool handle and associates it with the tool data in the server. Input the tool position number of the machine tool in the interface, and write the data into the machine tool.

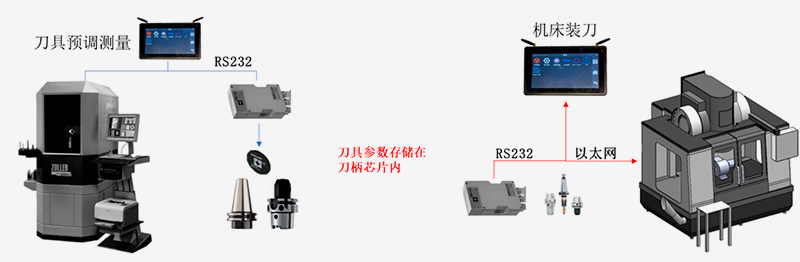

Scheme II RFID scheme of tool holder

Function description: store the tool measurement data through the tool handle RFID chip

Implementation method:

Workflow: (This scheme needs to configure the server and does not need to deploy the local area network)

1. Tool measurement, generating measurement data

2. HMI reads the measurement data and writes the data to the tool chip

3. The HMI on the machine tool side identifies the chip data, the interface inputs the tool position number of the machine tool, and the data is written into the machine tool (the data of the machine number and the position number to be installed on the tool handle can be defined in advance in the chip to realize data verification)

Why choose us

01

The company's technicians account for 70%. They have rich technical experience, understand the customer's workshop business and pain points, and can develop targeted solutions for different processing scenarios and implement them.

02

The product module is highly standardized and can be deployed quickly. At the same time, it can be customized and developed according to personalized needs, and its function configuration is flexible.

03

DMP data collection platform has strong compatibility and rich project experience. More than 50000 processing equipment have been collected, and the EMES project has served more than 200 customers.

04

A total of 15 offices nationwide implement localized services, which can quickly reach the customer's site and achieve accurate services.

Who is suitable for this product

Machining production enterprises, involving automobile, rail transit, engineering machinery, aerospace, military, medical, 3C, shipbuilding and other industries

What is a collaborative intelligent manufacturing management system

The collaborative manufacturing management system is a comprehensive information management system for the workshop executive level of manufacturing enterprises. Based on the relevant data of human, machine, material, method, environment and measurement, it realizes the collaborative interaction and management of the business level, and realizes digital management and lean production.

Product function module

DMP data acquisition platform

● DMP data acquisition platform is compatible with 95% controllers (CNC and PLC) on the market

● DMP acquisition platform can customize the variables and parameters to be collected by the equipment, and configure different acquisition frequencies

● Support secondary development. The user (upper system developer) can develop functional components, expand DMP functions, and realize user-defined logic

● Support multiple interfaces: OPC UA, Web Service, Web API, MQTT

Tool Data Management (TDM)

The TDM tool data management system integrates the independent tool magazine of a single machine tool into the system server by monitoring the tool data of the machine tool in real time, combining the tool inventory management and workpiece production data.

Improve the management efficiency of the whole process of purchasing and warehousing, tool distribution, tool installation, life monitoring, loss and scrap in the production process

Scheme I 2D code scheme of tool holder

Function description: the software system stores the 2D code of tool holder and tool measurement data in association

Implementation method:

Workflow: (This scheme needs to configure servers and deploy local area networks)

1. Tool measurement, generating measurement data

2. HMI reads measurement data, manually scans 2D code of tool handle, and server binds tool measurement data

3. The HMI on the machine tool side scans the 2D code of the tool handle and associates it with the tool data in the server. Input the tool position number of the machine tool in the interface, and write the data into the machine tool.

Scheme II RFID scheme of tool holder

Function description: store the tool measurement data through the tool handle RFID chip

Implementation method:

Workflow: (This scheme needs to configure the server and does not need to deploy the local area network)

1. Tool measurement, generating measurement data

2. HMI reads the measurement data and writes the data to the tool chip

3. The HMI on the machine tool side identifies the chip data, the interface inputs the tool position number of the machine tool, and the data is written into the machine tool (the data of the machine number and the position number to be installed on the tool handle can be defined in advance in the chip to realize data verification)

Why choose us

01

The company's technicians account for 70%. They have rich technical experience, understand the customer's workshop business and pain points, and can develop targeted solutions for different processing scenarios and implement them.

02

The product module is highly standardized and can be deployed quickly. At the same time, it can be customized and developed according to personalized needs, and its function configuration is flexible.

03

DMP data collection platform has strong compatibility and rich project experience. More than 50000 processing equipment have been collected, and the EMES project has served more than 200 customers.

04

A total of 15 offices nationwide implement localized services, which can quickly reach the customer's site and achieve accurate services.

Who is suitable for this product

Machining production enterprises, involving automobile, rail transit, engineering machinery, aerospace, military, medical, 3C, shipbuilding and other industries

COUNT FOR MORE

Please leave your contact information and our customer manager will contact you as soon as possible

COUNT FOR MORE

Please leave your contact information and our customer manager will contact you as soon as possible

Contact us

Hotline

400-828-3830

E-mail

Sales@wimisoft.com

-

Official account

Official account

Copyright © 2021 MasterLink All Rights Reserved.

苏ICP备19005118号-1

Product trial