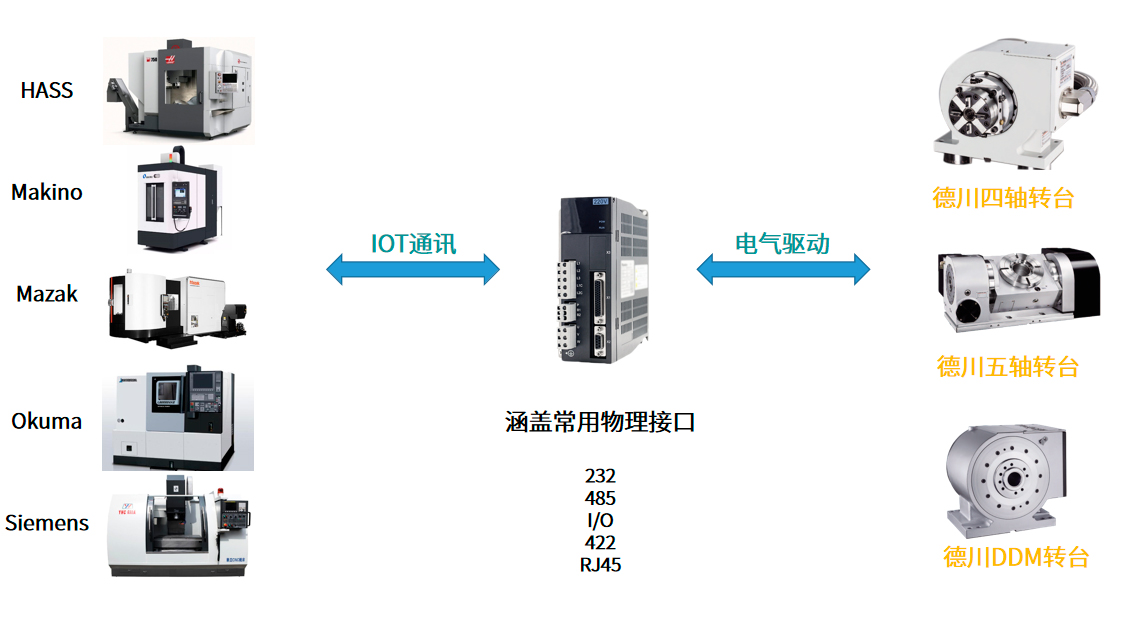

General four/five-axis driven and controlled integrated system

Special full circumference brake ring set is adopted, and 5Mpa oil pressure is guaranteed to be stable without leakage

General four/five-axis driven and controlled integrated system

Special full circumference brake ring set is adopted, and 5Mpa oil pressure is guaranteed to be stable without leakage

Home / General four/five-axis driven and controlled integrated system

Common problem

Authorization restrictions

Export restriction, original factory authority cannot be authorized.

I/O Limits

Because the system has no redundant I/O points, it cannot meet the production requirements.

Functional limitations

The production conditions cannot meet the process requirements.

Price cost

The motor is expensive and the input cost is too high.

Servo products

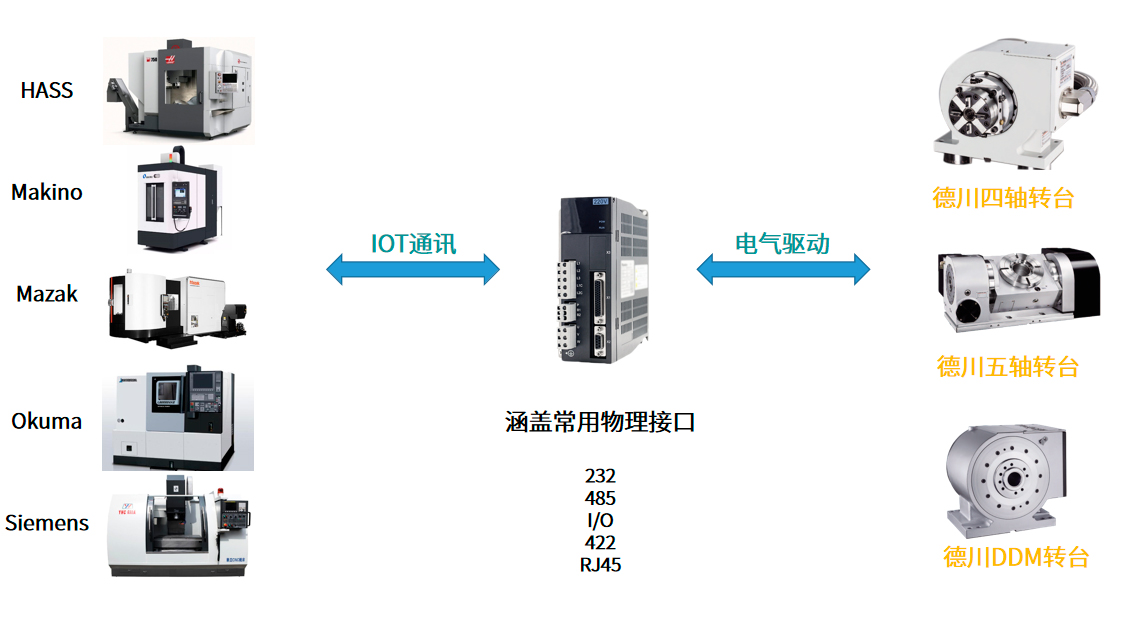

Embedded multi axis control system

Realize all kinds of algorithms before and after the operation of the turntable and the communication with various CNC systems.

TI Pro Series Drives

Drive and control the turntable for high-precision rotary positioning.

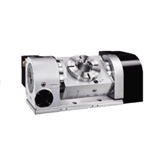

Tokugawa turntable

Drive and control the turntable for high-precision rotary positioning.

Intelligent operation screen (including handwheel)

This item is not required for turntable debugging, parameter modification and other operations.

T1 Pro series turntable drive solution

T1 Pro series servo function advantages

● Support manual, inching, positioning, wiring, handwheel, MDI and other operation modes

● Manual mode supports multiplying control, inching mode supports any step distance, and positioning mode supports any speed feed

● Connection mode, can receive CNC system commands through serial port, and support absolute positioning and speed mode

● Directional positioning supports multi axis control, which can support up to 9 axes

● Clamping and loosening control with solenoid valve

● Support any angle positioning, with command accuracy of 0.001 deg

● Support software limit to prevent interference

● Support reverse clearance compensation

● Support pitch error compensation

● Support phased unlocking function

● Support operation authority management

● Support emergency stop reset input, alarm abnormal output and other safety functions

● Support the display of coordinates, alarms, driver status and other information

● Support third-party motor and direct drive motor, compatible with Tomochuan and Renishaw. Encoder protocol such as Nikon

Our advantages

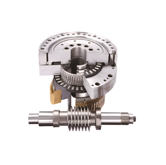

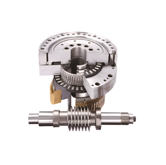

The transmission components are made of exclusive patented alloy copper, and the wear resistance is 260% higher than that of traditional components.

The main spindle and bearing are designed as a whole, with few combined parts and small relative error to provide the best rigidity.

The brake element has an exclusive double force piston structure, which doubles the acting area of the piston and greatly increases the braking force.

Special full circumference brake ring set is adopted,5Mpa oil pressure shall be stable without leakage.

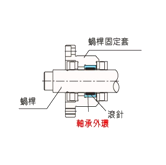

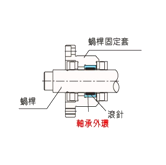

A bearing outer ring is arranged between the worm fixing sleeve and the needle roller to improve the concentricity of the worm and ensure high positioning accuracy.

All mounting surfaces of the motor are precision machined oil seal grooves. Trelleborg seal rings from Sweden are uniformly used, and the waterproof grade is IP65.

应用案例

The drive control system runs on the Dawen P200 machine tool and drives the DDR turntable

The control system runs on the Siemens 828D machine tool and drives the roller cam turntable

The control system runs on Jingdiao JD series machine tools and drives the harmonic turntable

Common problem

Authorization restrictions

Export restriction, original factory authority cannot be authorized.

I/O Limits

Because the system has no redundant I/O points, it cannot meet the production requirements.

Functional limitations

The production conditions cannot meet the process requirements.

Price cost

The motor is expensive and the input cost is too high.

Servo products

Embedded multi axis control system

Realize all kinds of algorithms before and after the operation of the turntable and the communication with various CNC systems.

TI Pro Series Drives

Drive and control the turntable for high-precision rotary positioning.

Tokugawa turntable

Drive and control the turntable for high-precision rotary positioning.

Intelligent operation screen (including handwheel)

Used to debug the turntable and modify parameters

This item is not required for use.

T1 Pro series turntable drive control solution

T1 Pro series servo function advantage

● Supports manual, inching, positioning, wire connection, handwheel, MDI and other operation modes

● Manual mode support rate control, inching mode support any step distance, positioning mode support any speed feed

● Connection mode, can accept CNC system instructions through the serial port, support absolute positioning and speed mode

● Directional positioning support multi-axis control, up to 9 axes

● With solenoid valve clamping, release control

● Support any Angle positioning, command accuracy of 0.001deg

● Support software limit, prevent interference

● Support reverse gap compensation

● Support pitch error compensation

● Supports unlock by installments

● Support operation rights management

● Support emergency stop reset input, alarm abnormal output and other safety functions

● Support coordinate, alarm, driver status and other information display

● Support third party motor and direct drive motor, compatible with Tama chuan, Renisau. Nikon and other encoder protocol

Our Advantages

The transmission components are made of exclusive copper alloy, and the wear resistance is 260% higher than that of traditional components.

Main shaft and bearing integrated design, fewer combined parts, small relative error to provide the best rigidity.

The brake element has an exclusive double force piston structure, which doubles the acting area of the piston and greatly increases the braking force.

Special full circumference brake ring set is adopted, and 5Mpa oil pressure is guaranteed to be stable without leakage.

A bearing outer ring is arranged between the worm fixing sleeve and the needle roller to improve the concentricity of the worm and ensure high positioning accuracy.

电机的所有安装面均为精密加工油封槽。统一使用瑞典Trelleborg密封圈,防水等级为IP65。

Application case

Drive control system runs on Dawei P200 machine tool, drive control DDR turntable

The control system is operated on Siemens 828D machine tool, drive control roller CAM turntable

The control system runs on JD series machine tool, drive - controlled harmonic turntable

COUNT FOR MORE

Please leave your contact information and our customer manager will contact you as soon as possible

COUNT FOR MORE

Please leave your contact information and our customer manager will contact you as soon as possible

Contact us

Hotline

400-828-3830

E-mail

Sales@wimisoft.com

-

Official account

Official account

Copyright © 2021 MasterLink All Rights Reserved.

苏ICP备19005118号-1

Product trial