Tool and process monitoring

Customized to improve machine tool utilization

Tool and process monitoring

Customized to improve machine tool utilization

Tool monitoring system product

■ Product introduction

The tool and process monitoring scheme of Montronix is applied in the worldwide metal machining industry. It is almost applicable to all types of cutting machining. Montronix monitoring scheme can recognize and diagnose problems in machining and help reduce the production cost and improve the usage rate of machine tools.No matter what type is your machine, which type of CN system you use, which field (auto, industry, aeronautics and astronautics, mould/tool manufacture, medical equipment, machine / tool manufacture, etc.) you are from, we can provide you with customized tool and process monitoring schemes.

Multiple optional sensors

Montronix is dedicated to developing high-end, intelligent sensors that can automatically optimize signals. Only precise signals can guarantee that reliable data assessment can also be realized under the high resolution.

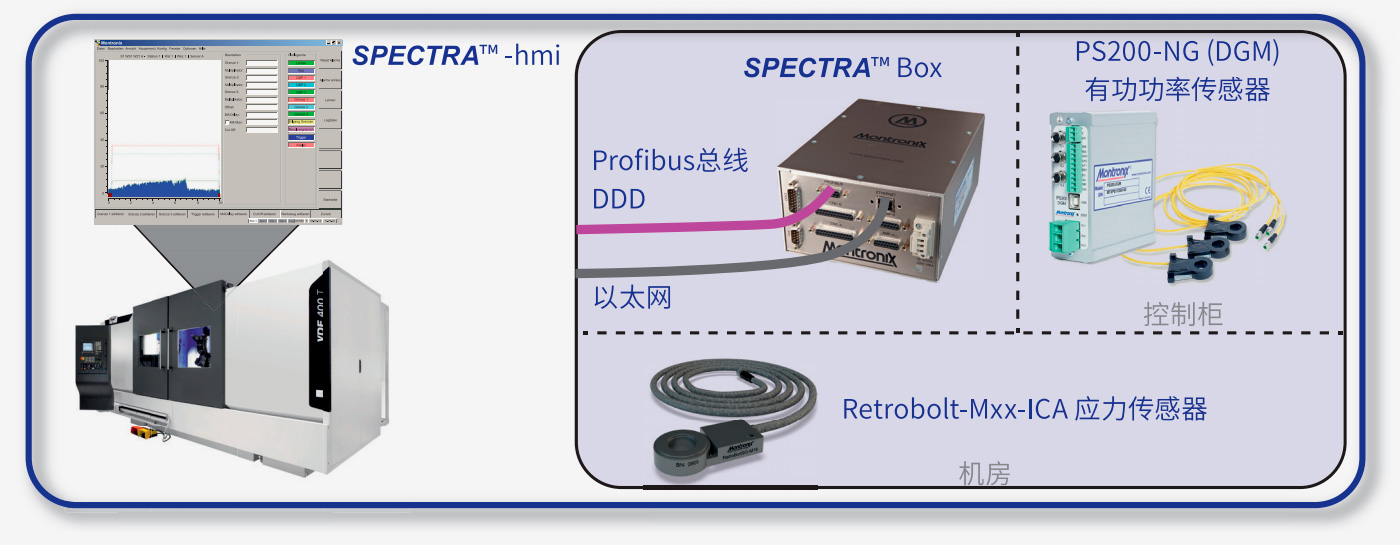

The process monitoring without a sensor but only digital driven data (DDD) is our basic configuration. The effective and intelligent algorithm guarantees the reliability of the process monitoring.

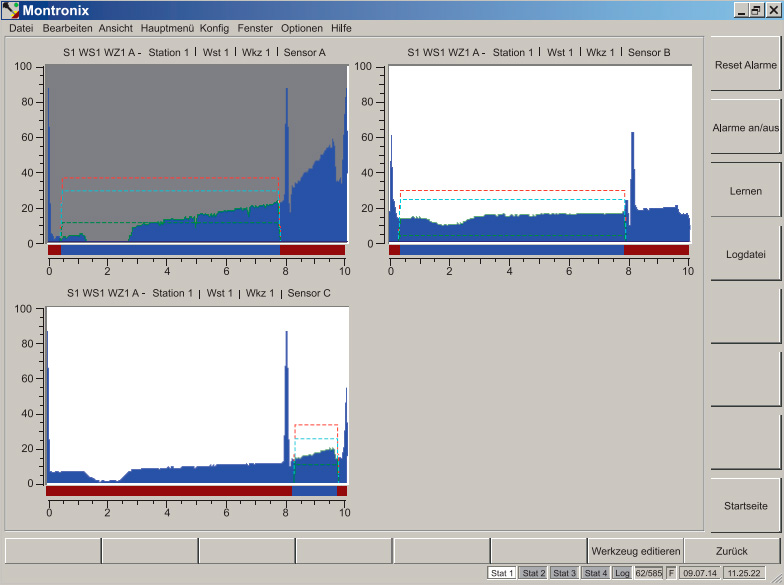

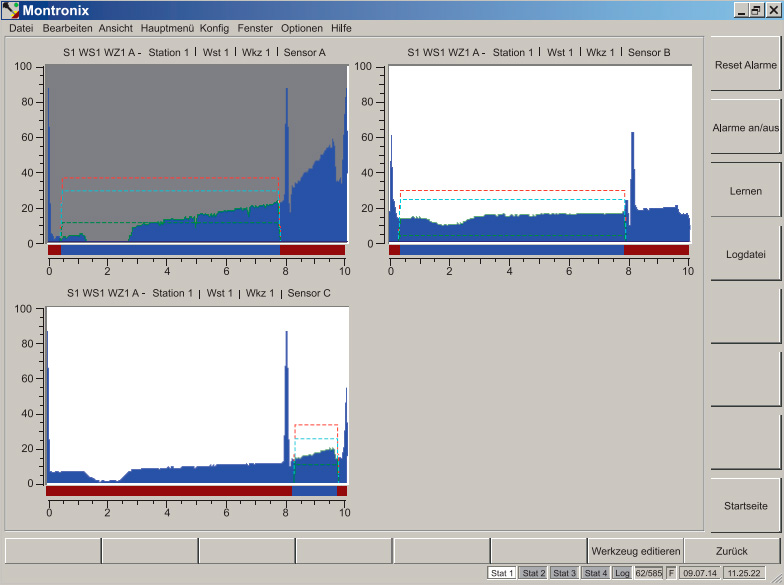

Process visualization software SPECTRA™ -hmi

This process visualization software SPECTRA™ -hmi is leading technologically now:

◆There are as many as 12 sensor window interfaces that can be configured freely.

◆Seven levels of password protection facilitates user permission management.

◆The monitoring boundary changes in the image form.

◆Offline log player configured with the filter analysis function.

◆Not restricted to the type of the operation system.

◆Fast and convenient parameter adjustment (fast and multiple types of edition).

◆Adaptive Control is realizable.

Application case

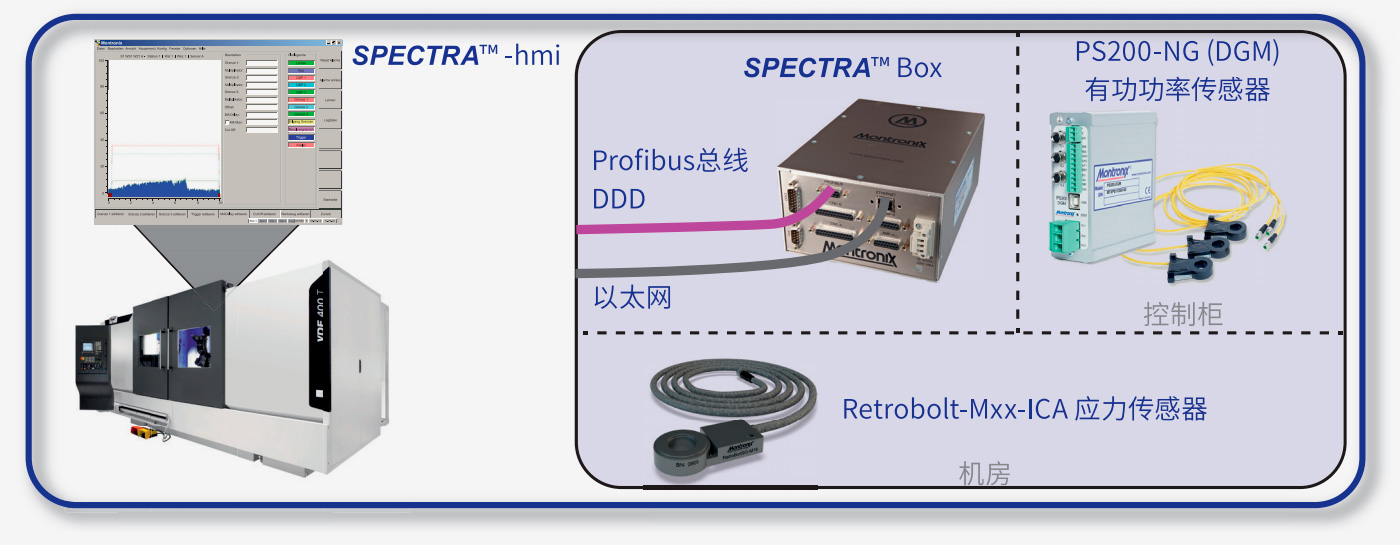

Lathe application case

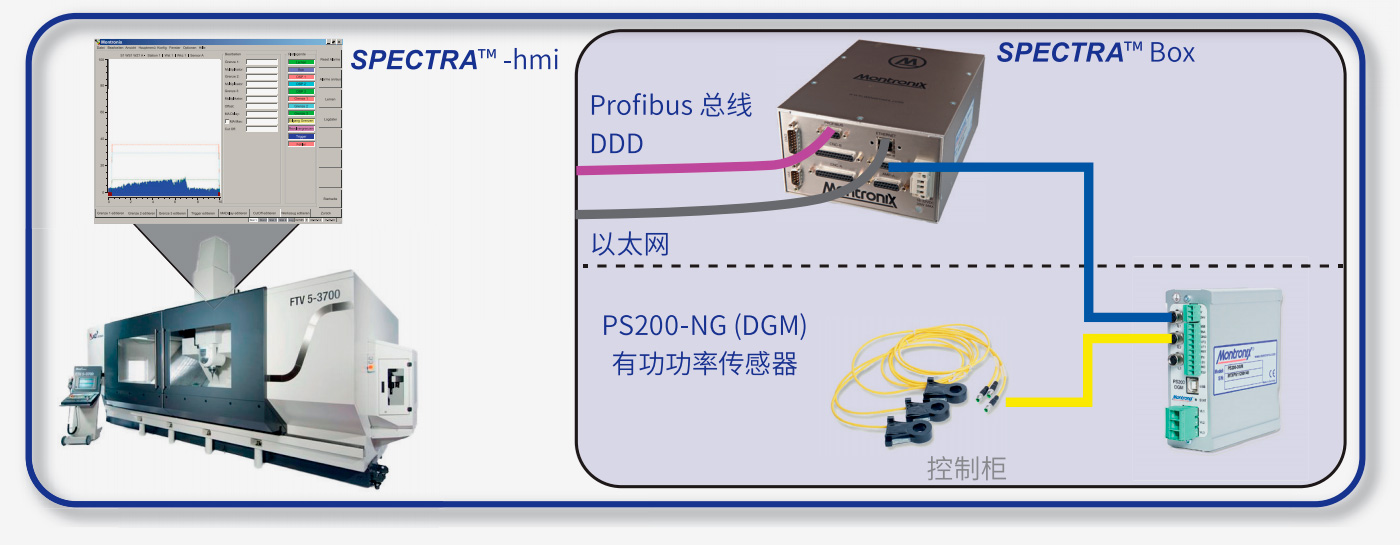

Machining center application case

◆Turning machining process monitoring

●Basic configuration: to solve the severe tool breakage problem

●Montronix recommends slight tool crazing, quality safety and collision identification

You only need Digital Drive Data

The active power sensor needs to be provided

◆System expansion: monitoring with power turret

●Drilling, milling and reaming process

●For diameter φ< 3 mm cutter and boring cutter

You only need Digital Drive Data

Active power sensor is required

◆Cutting process monitoring

●Drilling, milling and hinge thread machining process

●As for tools with a diameter <3 mm and the boring tool

You only need Digital Drive Data

The active power sensor needs to be provided

◆System expansion: more accurate identification of machining abnormalities

●Crash protection & Vibration overload protection

Broadband vibration sensor is required

Industrial 4.0

■ Applicable to industrial 4.0

◆All the data measured are transmitted in the form of a universal format to the LAN for big data analysis and management

◆Promote centralized and unified management of machines

◆Help establish the overview of the service condition of all the machine tools

◆Help maintain equipment in a planned and preventative way

◆Provide the client-end server function

Actual benefit of the customer

The detectable rate of tool breakage and damage is 99%!

The tool cost declines significantly!

The yield rate increases significantly!

Our business is worldwide

Tool monitoring system product

■ Product introduction

The tool and process monitoring scheme of Montronix is applied in the worldwide metal machining industry. It is almost applicable to all types of cutting machining. Montronix monitoring scheme can recognize and diagnose problems in machining and help reduce the production cost and improve the usage rate of machine tools.

No matter what type is your machine, which type of CN system you use, which field (auto, industry, aeronautics and astronautics, mould/tool manufacture, medical equipment, machine / tool manufacture, etc.) you are from, we can provide you with customized tool and process monitoring schemes.

Multiple optional sensors

Montronix is dedicated to developing high-end, intelligent sensors that can automatically optimize signals. Only precise signals can guarantee that reliable data assessment can also be realized under the high resolution.

The process monitoring without a sensor but only digital driven data (DDD) is our basic configuration. The effective and intelligent algorithm guarantees the reliability of the process monitoring.

Process visualization software SPECTRA™ -hmi

This process visualization software SPECTRA™ -hmi is leading technologically now:

◆There are as many as 12 sensor window interfaces that can be configured freely.

◆Seven levels of password protection facilitates user permission management.

◆The monitoring boundary changes in the image form.

◆Offline log player configured with the filter analysis function.

◆Not restricted to the type of the operation system.

◆Fast and convenient parameter adjustment (fast and multiple types of edition).

◆Adaptive Control is realizable.

Application case

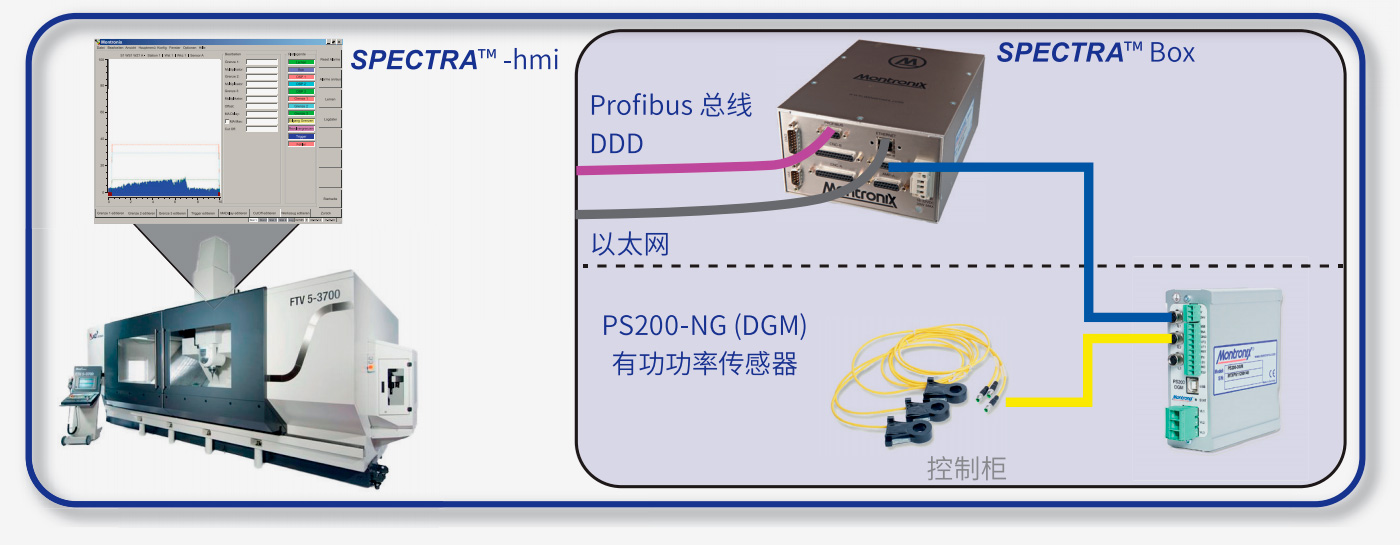

Lathe application case

◆Turning machining process monitoring

●Basic configuration: to solve the severe tool breakage problem

●Montronix recommends slight tool crazing, quality safety and collision identification

You only need Digital Drive Data

Stress sensor needs to be provided

◆System extension: with the powerful tool library monitoring

●Drilling, milling and hinge thread machining process

●As for tools with a diameter φ<3 mm and the boring tool

You only need Digital Drive Data

Active power sensor is required

Machining center application case

◆Cutting process monitoring

●Drilling, milling and hinge thread machining process

●As for tools with a diameter φ<3 mm and the boring tool

You only need Digital Drive Data

The active power sensor needs to be provided

◆System extension: more precise machining abnormality recognition

●Collision protection & vibration overload protection

A broadband vibration sensor needs to be provided

Industrial 4.0

■ Applicable to industrial 4.0

◆All the data measured are transmitted in the form of a universal format to the LAN for big data analysis and management

◆Promote centralized and unified management of machines

◆Help establish the overview of the service condition of all the machine tools

◆Help maintain equipment in a planned and preventative way

◆Provide the client-end server function

Actual benefit of the customer

The detectable rate of tool breakage and damage is 99%!

The tool cost declines significantly!

The yield rate increases significantly!

Our business is worldwide

COUNT FOR MORE

Please leave your contact information and our customer manager will contact you as soon as possible

COUNT FOR MORE

Please leave your contact information and our customer manager will contact you as soon as possible

Contact us

Hotline

400-828-3830

E-mail

Sales@wimisoft.com

-

Official account

Official account

Copyright © 2021 MasterLink All Rights Reserved.

苏ICP备19005118号-1

Product trial